Decentralized production would be the new focus in manufacturing, Hon Hai Precision Industry Co (鴻海精密) chairman Young Liu (劉揚偉) yesterday told an online forum held by the Market Intelligence & Consulting Institute (MIC, 產業情報研究所).

“The COVID-19 pandemic exerted a heavy impact on supply chains as well as production ... [production] would no longer be concentrated in solely one country, this is the end of what we used to call world factories,” Liu said during a panel discussion hosted by MIC director Victor Tsan (詹文男).

As the US and China continue to dominate and sway international relations, the rest of the world is now more than ever focused on developing their economies, which would help to divide labor, Liu said.

“I think all countries have come to the realization following the coronavirus outbreak that manufacturing remains essential [to economic development],” Liu said.

He pointed to the US as an example, alluding to Taiwan Semiconductor Manufacturing Co’s (TSMC, 台積電) pledge to set up an advanced wafer foundry in Arizona.

Hon Hai also has a project to build an LCD fab in Wisconsin.

Claiming more than 16 production sites around the world, Hon Hai has over the past two years accelerated its relocation to popular manufacturing destinations, such as India and Vietnam, but its principal operations remain in China, which accounts for about 70 percent of sales.

However, electronics manufacturer Qisda Corp (佳世達) chairman and president Peter Chen (陳其宏) offered a different view.

“The current manufacturing landscape is unlikely to change in the short term. Why? The cost,” Chen said, adding that “it decides everything from consumer behavior to company competitiveness.”

Nevertheless, Chen acknowledged the importance of risk-diverting strategies that involve production relocation.

Pointing to the company’s three-step plan, Chen said Qisda last year moved part of its production to Taiwan in anticipation of rising trade tensions between the US and China.

Due to relatively high production costs in Taiwan, Qisda has further relocated some production to Southeast Asia, where it launched mass production in February. The company makes entry-level LCD monitors in Vietnam’s Ha Nam Province.

A myriad of Taiwanese firms have moved their production to Southeast Asia since last year in a bid to cushion the blow of US duties levied on goods made in their China-based production sites.

“Of course, we would consider setting up production in the US as a last resort,” Chen said, adding that Qisda has negotiated a partnership with two local firms to establish assembly sites near transport hubs in the US.

“However, eventually, it would all boil down to costs ... we cannot afford to overly divert [production],” Chen said, adding that production, although split up, would still be mainly concentrated in a handful of countries.

Real estate agent and property developer JSL Construction & Development Co (愛山林) led the average compensation rankings among companies listed on the Taiwan Stock Exchange (TWSE) last year, while contract chipmaker Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) finished 14th. JSL Construction paid its employees total average compensation of NT$4.78 million (US$159,701), down 13.5 percent from a year earlier, but still ahead of the most profitable listed tech giants, including TSMC, TWSE data showed. Last year, the average compensation (which includes salary, overtime, bonuses and allowances) paid by TSMC rose 21.6 percent to reach about NT$3.33 million, lifting its ranking by 10 notches

Popular vape brands such as Geek Bar might get more expensive in the US — if you can find them at all. Shipments of vapes from China to the US ground to a near halt last month from a year ago, official data showed, hit by US President Donald Trump’s tariffs and a crackdown on unauthorized e-cigarettes in the world’s biggest market for smoking alternatives. That includes Geek Bar, a brand of flavored vapes that is not authorized to sell in the US, but which had been widely available due to porous import controls. One retailer, who asked not to be named, because

SEASONAL WEAKNESS: The combined revenue of the top 10 foundries fell 5.4%, but rush orders and China’s subsidies partially offset slowing demand Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) further solidified its dominance in the global wafer foundry business in the first quarter of this year, remaining far ahead of its closest rival, Samsung Electronics Co, TrendForce Corp (集邦科技) said yesterday. TSMC posted US$25.52 billion in sales in the January-to-March period, down 5 percent from the previous quarter, but its market share rose from 67.1 percent the previous quarter to 67.6 percent, TrendForce said in a report. While smartphone-related wafer shipments declined in the first quarter due to seasonal factors, solid demand for artificial intelligence (AI) and high-performance computing (HPC) devices and urgent TV-related orders

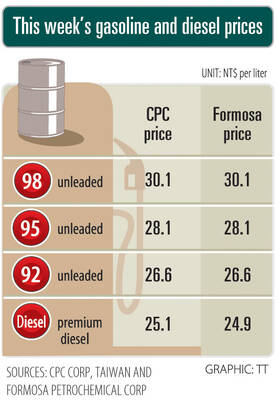

Prices of gasoline and diesel products at domestic fuel stations are this week to rise NT$0.2 and NT$0.3 per liter respectively, after international crude oil prices increased last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week snapped a two-week losing streak as the geopolitical situation between Russia and Ukraine turned increasingly tense, CPC said in a statement. News that some oil production facilities in Alberta, Canada, were shut down due to wildfires and that US-Iran nuclear talks made no progress also helped push oil prices to a significant weekly gain, Formosa said