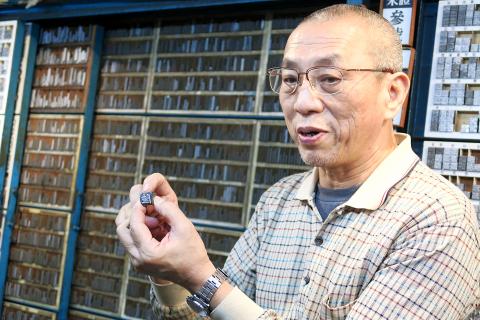

Chang Chieh-kuan (張介冠), the owner of the last Chinese character letterpress and the last lead-character moldmaker in Taiwan, has long dreamed about passing on his work so that the dying technique of which he is a master practitioner can be preserved.

However, just days before his humble shop, Rixing Type Foundry (日星鑄字行), squeezed into a small lane on Taipei’s Taiyuan Road (太原路), celebrated its 48th anniversary yesterday, 65-year-old Chang came to believe those hopes were a pipe dream and that it would be impossible to cultivate such talent.

“I will just carve as long as I can,” Chang said, as he strives to preserve the culture of Chinese letterpress printing against the passing of time and advent of new technology.

Photo: CNA

Rixing Type Foundry is possibly home to the last remaining collection of traditional Chinese movable type character molds in the world. It possesses 120,000 molds of different characters in a wide range of sizes and three different typefaces — kai ti (楷體) (regular script), song ti (宋體) and hei ti (黑體) (sans-serif black) — and has more than 10 million lead character pieces for printing or sale.

The foundry also has several molding machines that allow it to fabricate 3D lead type pieces, making it the last and only foundry of its kind in Taiwan.

However, the business might fade into history because many of its bronze molds are either partly or wholly worn.

What makes the situation even more daunting, as Chang has long feared, is that there is no way to train anyone in the skills needed to repair bronze molds for lead type.

It was in 1979 when Chang, a trained steel mechanic, started working at the lead foundry his father opened in 1969.

Training in the crafting and mending of lead type bronze molds should really start at 12 or 13, because it takes 10 to 15 years to master the skills, he said.

In addition, traditional masters remain at the peak of their abilities for about 10 years, at which point they have to rely more on experience as their eyesight deteriorates, Chang said.

“These days it is impossible to acquire apprentices aged 12 or 13. If people come here after graduating from college or university, their eyesight is already not good enough to do the job,” Chang said.

Joking that he was “forced” to enter the business, the lead type foundry master said he now often spends most of the day at his desk, mending the worn molds.

However, he said he never grows tired of the repetitive nature of tasks such as recrafting, scanning and correcting character types, which can seem extremely monotonous to an outsider. “I do not know how long the bronze molds at Rixing will last, as many of them are already badly worn,” Chang said. “I am now 65 years old. It will take another 65 years to repair them all.”

A skilled foundry master can mend a maximum of five character molds per day, he said, adding that to restore all 120,000 molds at Rixing Foundry would be extremely expensive.

Despite the time-consuming and labor intensive nature of the work, Chang told visitors to his shop that lead type imbues Chinese characters with a grandeur that digital printing cannot replicate.

It is like the difference between listening to music on vinyl or CD; it is all about the warm sentiment lead type conveys, he said.

Early this year Rixing launched a type bronze mold restoration project in the hope that an online fundraising program would help raise the funds needed to preserve its endangered bronze molds so that they can be passed on in their entirety.

“We want not only to preserve lead type, but also an era,” Chang said in a post on the project’s Web site at rixing2017.com.

“The ideal situation would be for people to express their support for the preservation of this culture through their everyday life choices,” he said.

Intel Corp chief executive officer Lip-Bu Tan (陳立武) is expected to meet with Taiwanese suppliers next month in conjunction with the opening of the Computex Taipei trade show, supply chain sources said on Monday. The visit, the first for Tan to Taiwan since assuming his new post last month, would be aimed at enhancing Intel’s ties with suppliers in Taiwan as he attempts to help turn around the struggling US chipmaker, the sources said. Tan is to hold a banquet to celebrate Intel’s 40-year presence in Taiwan before Computex opens on May 20 and invite dozens of Taiwanese suppliers to exchange views

Application-specific integrated circuit designer Faraday Technology Corp (智原) yesterday said that although revenue this quarter would decline 30 percent from last quarter, it retained its full-year forecast of revenue growth of 100 percent. The company attributed the quarterly drop to a slowdown in customers’ production of chips using Faraday’s advanced packaging technology. The company is still confident about its revenue growth this year, given its strong “design-win” — or the projects it won to help customers design their chips, Faraday president Steve Wang (王國雍) told an online earnings conference. “The design-win this year is better than we expected. We believe we will win

Chizuko Kimura has become the first female sushi chef in the world to win a Michelin star, fulfilling a promise she made to her dying husband to continue his legacy. The 54-year-old Japanese chef regained the Michelin star her late husband, Shunei Kimura, won three years ago for their Sushi Shunei restaurant in Paris. For Shunei Kimura, the star was a dream come true. However, the joy was short-lived. He died from cancer just three months later in June 2022. He was 65. The following year, the restaurant in the heart of Montmartre lost its star rating. Chizuko Kimura insisted that the new star is still down

While China’s leaders use their economic and political might to fight US President Donald Trump’s trade war “to the end,” its army of social media soldiers are embarking on a more humorous campaign online. Trump’s tariff blitz has seen Washington and Beijing impose eye-watering duties on imports from the other, fanning a standoff between the economic superpowers that has sparked global recession fears and sent markets into a tailspin. Trump says his policy is a response to years of being “ripped off” by other countries and aims to bring manufacturing to the US, forcing companies to employ US workers. However, China’s online warriors