Solar energy may finally get its day in the sun. The high costs that for years made it impractical as a mainstream source of energy are plummeting. Real-estate companies are racing to install solar panels on office buildings, utilities are erecting large solar panel “farms” near big cities and in desolate deserts and creative financing plans are making solar more realistic than ever for homes.

Solar power installations doubled in the US last year and are expected to double again this year. More solar energy is being planned than any other power source, including nuclear, coal, natural gas and wind.

“We are at the beginning of a turning point,” says Andrew Beebe, who runs global sales for Suntech Power Holdings Co (尚德), a manufacturer of solar panels.

Photo: Reuters

Solar’s share of the power business remains tiny, but its promise is great. The sun splashes more clean energy on the planet in one hour than humans use in a year, and daytime is when power is needed most. Moreover, solar panels can be installed near where people use power, reducing or eliminating the costs of moving power through a grid.

Solar power has been held back by costs. It’s still about three times more expensive than electricity produced by natural gas, according to estimates by the US Energy Information Administration.

However, the financial barriers are falling fast. Solar panel prices have plunged by two-thirds since 2008, making it easier for installers to market solar’s financial benefits and not simply its environmental ones. Homeowners who want to go solar can do so for free and pay the same or less for their power.

Last month, two of the nation’s biggest utilities, Exelon Corp and NextEra Energy Inc, each acquired a large California solar power farm in the early stages of development. Another utility, NRG Energy Inc, has announced a plan with Bank of America and the real estate firm Prologis Inc to spend US$1.4 billion to install solar systems on 750 commercial rooftops.

Nationwide, solar power installations grew by 102 percent from 2009 to last year, by far the fastest rate in the past five years.

Making solar affordable still requires large tax breaks and other subsidies from federal and state governments. The main federal subsidy pays for 30 percent of the cost of a residential system. When state and other subsidies are added, as much as 75 percent of the cost can be covered.

However, prices of solar panels, the squares of crystalline silicon or thin layers of metal films that turn the sun’s rays into electricity, are falling so fast that its advocates now credibly claim that solar will be able to compete with fossil fuels even when the federal solar subsidy shrinks by two-thirds in 2016.

The falling prices have made it easier for solar installers to raise the money needed to grow. And they’ve made solar power systems so affordable they can appeal to homeowners who want to save on their electric bill, not just reduce their environmental impact.

Some installers are teaming up with big hardware chains Home Depot and Lowe’s in an effort to expose solar to customers who might not otherwise consider it.

Solar panel prices have been declining for years because of lower costs for polycrystalline silicon, the main raw material for most solar panels, and larger-scale manufacturing, especially in Asia. In the last six months, demand has dropped sharply in Germany, the world’s biggest solar market, in response to shrinking subsidies. This has created a global glut of solar panels and accelerated the decline in prices.

Solar panels, which are priced based on the amount of power they can produce during full sunshine, sold for US$1.34 per watt in the middle of last month, according to data from Bloomberg New Energy Finance. That’s down from US$1.90 at the beginning of last year. In 2008, they sold for US$4 a watt.

The glut has been gut-wrenching for companies that make solar panels. Many of them remain profitable and are growing, but three US panel makers have filed for bankruptcy in two months, including Solyndra, a solar panel maker that received a US$528 million federal loan.

Falling profit margins are scaring investors. The stock price of First Solar Inc has fallen from US$170 in April to US$53.77. Suntech has fallen from US$11 to US$2.07 over the same period.

The Solyndra bankruptcy has sparked a political uproar. Republicans have accused US President Barack Obama’s administration of pushing for Solyndra’s loan for political reasons and have used the bankruptcy to question Obama’s plan to help boost the economy by subsidizing clean energy projects.

The market will not get any easier for small solar panel makers. General Electric Co, Samsung Electronics Co and other big companies are entering the market.

However, what has been treacherous for solar panel makers has been a boon for companies that market and install solar systems, for companies that make electronics and other parts for solar systems, and for solar customers.

To be sure, solar is growing from a very small base. All of the panels now installed across the nation produce enough electricity to power 600,000 homes, or about as much electricity as one large coal-fired power plant.

There are 30,000 megawatts worth of solar projects awaiting approval in the US, according to the American Public Power Association. Not all of them will be built, either because of regulatory or financial hurdles. However, even if only half that is ultimately built, it would be five times what is already installed.

IN THE AIR: While most companies said they were committed to North American operations, some added that production and costs would depend on the outcome of a US trade probe Leading local contract electronics makers Wistron Corp (緯創), Quanta Computer Inc (廣達), Inventec Corp (英業達) and Compal Electronics Inc (仁寶) are to maintain their North American expansion plans, despite Washington’s 20 percent tariff on Taiwanese goods. Wistron said it has long maintained a presence in the US, while distributing production across Taiwan, North America, Southeast Asia and Europe. The company is in talks with customers to align capacity with their site preferences, a company official told the Taipei Times by telephone on Friday. The company is still in talks with clients over who would bear the tariff costs, with the outcome pending further

NEGOTIATIONS: Semiconductors play an outsized role in Taiwan’s industrial and economic development and are a major driver of the Taiwan-US trade imbalance With US President Donald Trump threatening to impose tariffs on semiconductors, Taiwan is expected to face a significant challenge, as information and communications technology (ICT) products account for more than 70 percent of its exports to the US, Chung-Hua Institution for Economic Research (CIER, 中華經濟研究院) president Lien Hsien-ming (連賢明) said on Friday. Compared with other countries, semiconductors play a disproportionately large role in Taiwan’s industrial and economic development, Lien said. As the sixth-largest contributor to the US trade deficit, Taiwan recorded a US$73.9 billion trade surplus with the US last year — up from US$47.8 billion in 2023 — driven by strong

A proposed 100 percent tariff on chip imports announced by US President Donald Trump could shift more of Taiwan’s semiconductor production overseas, a Taiwan Institute of Economic Research (TIER) researcher said yesterday. Trump’s tariff policy will accelerate the global semiconductor industry’s pace to establish roots in the US, leading to higher supply chain costs and ultimately raising prices of consumer electronics and creating uncertainty for future market demand, Arisa Liu (劉佩真) at the institute’s Taiwan Industry Economics Database said in a telephone interview. Trump’s move signals his intention to "restore the glory of the US semiconductor industry," Liu noted, saying that

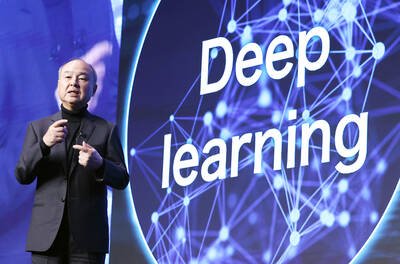

AI: Softbank’s stake increases in Nvidia and TSMC reflect Masayoshi Son’s effort to gain a foothold in key nodes of the AI value chain, from chip design to data infrastructure Softbank Group Corp is building up stakes in Nvidia Corp and Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the latest reflection of founder Masayoshi Son’s focus on the tools and hardware underpinning artificial intelligence (AI). The Japanese technology investor raised its stake in Nvidia to about US$3 billion by the end of March, up from US$1 billion in the prior quarter, regulatory filings showed. It bought about US$330 million worth of TSMC shares and US$170 million in Oracle Corp, they showed. Softbank’s signature Vision Fund has also monetized almost US$2 billion of public and private assets in the first half of this year,