Toshiba Corp, the world’s -second-largest maker of flash-memory chips, will shut one of its oldest plants ahead of schedule and outsource some semiconductor output, accelerating efforts to boost the unit’s profitability.

Toshiba will shut its No. 2 plant in Yokkaichi, central Japan, by the end of next month and phase out low-end chips used in products such as memory sticks, Kiyoshi Kobayashi, president of the semiconductor division, said on Wednesday in an interview. Toshiba will also farm out production of so-called logic chips next year to cut costs at a business that’s “barely breaking even,” he said.

The moves by Kobayashi, who took the helm at the semiconductor unit five months ago, are part of Toshiba’s efforts to focus on its main business of making chips that save photos and songs in smartphones including Apple Inc’s iPhone. Sales of flash memory will probably rise 25 percent to US$22.5 billion next year, according to researcher iSuppli Corp.

PHOTO: REUTERS

Toshiba’s fortunes rise and fall with those of its chip unit, a business the company forecasts will make up about 17 percent of revenue totaling ¥7 trillion (US$84 billion) this year. The chip business broke even last year after incurring a ¥280 billion operating loss in the previous year, when memory prices plunged 70 percent.

Kobayashi said second-half prices of flash memory may fall more than the 10 percent forecast last week by Toshiba senior executive vice president Fumio Muraoka.

Spot prices of benchmark flash chips have fallen 17 percent since last month, according to data from DRAMexchange.com.

“Part of me thinks the numbers might not turn out in the way Muraoka presented them,” Kobayashi said at the company’s headquarters. “We’re in a tug-of-war with customers on prices.”

About 1,000 employees who work at the No. 2 plant will be transferred to facilities in the same manufacturing site, including a facility under construction that’s set to open in the summer, the executive said.

The Yokkaichi factory, which processes 8-inch (203mm) silicon wafers, was opened in 1996, when Toshiba was still producing memory chips for PCs.

Toshiba will outsource the -production of next-generation system LSI chips, which are being jointly developed with IBM Corp, by as early as next fiscal year, Kobayashi said.

System LSI chips, whose functions range from processing images for television screens to crunching data, will account for 30 percent of the ¥1.2 trillion in sales Toshiba forecasts from its chip business this year, the company said.

Real estate agent and property developer JSL Construction & Development Co (愛山林) led the average compensation rankings among companies listed on the Taiwan Stock Exchange (TWSE) last year, while contract chipmaker Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) finished 14th. JSL Construction paid its employees total average compensation of NT$4.78 million (US$159,701), down 13.5 percent from a year earlier, but still ahead of the most profitable listed tech giants, including TSMC, TWSE data showed. Last year, the average compensation (which includes salary, overtime, bonuses and allowances) paid by TSMC rose 21.6 percent to reach about NT$3.33 million, lifting its ranking by 10 notches

SEASONAL WEAKNESS: The combined revenue of the top 10 foundries fell 5.4%, but rush orders and China’s subsidies partially offset slowing demand Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) further solidified its dominance in the global wafer foundry business in the first quarter of this year, remaining far ahead of its closest rival, Samsung Electronics Co, TrendForce Corp (集邦科技) said yesterday. TSMC posted US$25.52 billion in sales in the January-to-March period, down 5 percent from the previous quarter, but its market share rose from 67.1 percent the previous quarter to 67.6 percent, TrendForce said in a report. While smartphone-related wafer shipments declined in the first quarter due to seasonal factors, solid demand for artificial intelligence (AI) and high-performance computing (HPC) devices and urgent TV-related orders

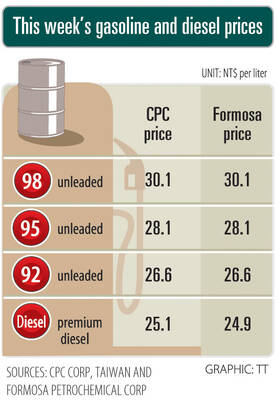

Prices of gasoline and diesel products at domestic fuel stations are this week to rise NT$0.2 and NT$0.3 per liter respectively, after international crude oil prices increased last week, CPC Corp, Taiwan (台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. International crude oil prices last week snapped a two-week losing streak as the geopolitical situation between Russia and Ukraine turned increasingly tense, CPC said in a statement. News that some oil production facilities in Alberta, Canada, were shut down due to wildfires and that US-Iran nuclear talks made no progress also helped push oil prices to a significant weekly gain, Formosa said

MINERAL DIPLOMACY: The Chinese commerce ministry said it approved applications for the export of rare earths in a move that could help ease US-China trade tensions Chinese Vice Premier He Lifeng (何立峰) is today to meet a US delegation for talks in the UK, Beijing announced on Saturday amid a fragile truce in the trade dispute between the two powers. He is to visit the UK from yesterday to Friday at the invitation of the British government, the Chinese Ministry of Foreign Affairs said in a statement. He and US representatives are to cochair the first meeting of the US-China economic and trade consultation mechanism, it said. US President Donald Trump on Friday announced that a new round of trade talks with China would start in London beginning today,