The fevered buildup to today’s iPad launch has demonstrated the brute efficiency of the little-known Asian suppliers responsible for turning Apple’s design vision into reality.

Taiwanese touch-screen makers, South Korean chip producers and Chinese battery manufacturers have been adding workers by the hundred to staff extra factory shifts and meet double the forecast demand.

Along the way, the component makers have navigated technical hurdles posed by a product that Apple boasts will remake personal computing.

“iPad suppliers forecast eight to 10 million shipments in this calendar year, up from prior expectations of five-plus million,” Morgan Stanley analyst Katy Huberty said.

The iPad, like the iPhone and iPod before it, is the offspring of a globalized economy where components and assembly are sourced to low-cost, high-speed manufacturers.

Simplo Technology Co (新普) is Taiwanese, but makes components for Apple at its plant in Changshu, in China’s Jiangsu Province, and has recently shifted into overdrive to fulfill orders for iPad batteries.

Tapping China’s massive labor market, the plant’s “Apple Manufacturing Department” has added 700 workers since Lunar New Year and now employs 1,800 people.

“The product has a tight deadline, and we’ve been increasing staff numbers to make it,” said an executive at the department, giving her surname as Zhou. “The output of the iPad battery is now 50 percent higher than it was in January.”

As a rule, Apple’s Asian partners are loath to talk, bound by confidentiality agreements and Apple’s reluctance to allow outsiders a glimpse of its inner workings.

But in Taiwan alone, 20 enterprises are involved in making the iPad, said Jonathan Luo of the Topology Research Institute (拓墣產業研究所), a think tank in Taipei.

Millions of iPads will be assembled in China by Taiwan-based Foxconn (富士康), also known as the Hon Hai Group (鴻海集團), analysts and technology Web sites say.

Taiwan’s Catcher Technologies (可成企業) manufactures the device’s silver casing, Novatek Microelectronics makes LCD drivers, and Dynapack International makes batteries, Luo said.

South Korea’s Samsung is widely believed to have a hand in the super-fast processor that drives the iPad, along with lesser known chip foundries in Taiwan.

The multitude of suppliers is part of Apple’s strategy of having ample back-up mechanisms in place, ensuring delivery even when the unexpected happens.

One example is the production of the high-resolution touch-screen, new territory for Apple and its suppliers due to its 25cm size.

“Most of the components in the iPad are mature items,” said Mars Hsu, an analyst with Grand Cathay Securities (大華證券). “The only component that may have had production problems is the touch-screen.”

The main supplier has been TPK Touch Solution (宸鴻科技). But in a possible indication of technical obstacles, Apple appears to have switched at least some of its screen orders to Wintek Corp (勝華科技), Hsu said.

While customers are set to discover whether Apple’s hype is worth it, the iPad has shown what the global integrated economy can engineer in a short space of time.

IN THE AIR: While most companies said they were committed to North American operations, some added that production and costs would depend on the outcome of a US trade probe Leading local contract electronics makers Wistron Corp (緯創), Quanta Computer Inc (廣達), Inventec Corp (英業達) and Compal Electronics Inc (仁寶) are to maintain their North American expansion plans, despite Washington’s 20 percent tariff on Taiwanese goods. Wistron said it has long maintained a presence in the US, while distributing production across Taiwan, North America, Southeast Asia and Europe. The company is in talks with customers to align capacity with their site preferences, a company official told the Taipei Times by telephone on Friday. The company is still in talks with clients over who would bear the tariff costs, with the outcome pending further

NEGOTIATIONS: Semiconductors play an outsized role in Taiwan’s industrial and economic development and are a major driver of the Taiwan-US trade imbalance With US President Donald Trump threatening to impose tariffs on semiconductors, Taiwan is expected to face a significant challenge, as information and communications technology (ICT) products account for more than 70 percent of its exports to the US, Chung-Hua Institution for Economic Research (CIER, 中華經濟研究院) president Lien Hsien-ming (連賢明) said on Friday. Compared with other countries, semiconductors play a disproportionately large role in Taiwan’s industrial and economic development, Lien said. As the sixth-largest contributor to the US trade deficit, Taiwan recorded a US$73.9 billion trade surplus with the US last year — up from US$47.8 billion in 2023 — driven by strong

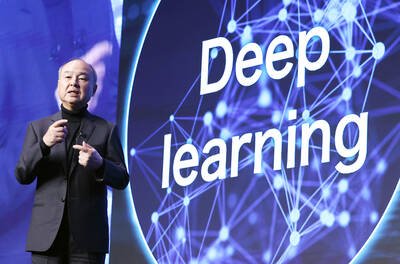

AI: Softbank’s stake increases in Nvidia and TSMC reflect Masayoshi Son’s effort to gain a foothold in key nodes of the AI value chain, from chip design to data infrastructure Softbank Group Corp is building up stakes in Nvidia Corp and Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the latest reflection of founder Masayoshi Son’s focus on the tools and hardware underpinning artificial intelligence (AI). The Japanese technology investor raised its stake in Nvidia to about US$3 billion by the end of March, up from US$1 billion in the prior quarter, regulatory filings showed. It bought about US$330 million worth of TSMC shares and US$170 million in Oracle Corp, they showed. Softbank’s signature Vision Fund has also monetized almost US$2 billion of public and private assets in the first half of this year,

POWELL SUCCESSOR: US Fed Governor Adriana Kugler’s resignation gives Donald Trump an opening on the board, potentially accelerating his decision on the next chair US President Donald Trump suddenly has a chance to fill an opening at the US Federal Reserve earlier than expected, after Fed Governor Adriana Kugler announced her resignation on Friday. It might also force him to pick the next Fed chair months sooner than he had anticipated. “The ball is now in Trump’s court,” LH Meyer/Monetary Policy Analytics Inc economist Derek Tang said. “Trump is the one who’s been putting pressure on the Fed to do this and that, and Trump says he wants to have his own people on. So now he has the opportunity.” Kugler’s exit unfolds amid unprecedented public pressure