A giant silver teapot shines in the pale sun outside the Alessi factory, its scale a measure of how in the 1980s and 1990s Italian kitchenware, from espresso-makers to lemon-squeezers, grew into objects of desire.

But the allure of great design and artisanal quality is failing to insulate this narrow valley and home of Lagostina, Alessi and Bialetti from Italy’s worst post-war recession.

So modern that people often think they are new, the brands have grown through decades with the inhabitants of the valley near the Alps surviving war, poverty, landslides and avalanches. Now they are feeling the pinch.

PHOTO: REUTERS

“Are we immune to the crisis? The answer is no,” said Alberto Alessi, 62, design director and grandson of Giovanni Alessi, a lathe worker who founded the family firm in 1921.

Competition from low-cost Chinese or Romanian manufacturers, outsourcing and recession have shut down many family firms and dampened Italian manufacturing, which accounts for about one-fifth of output from the eurozone’s third-largest economy.

Houseware exports, the main source of income for an area heavily reliant on manufacturing, fell 59 percent year-on-year to 62 million euros (US$92 million) in the first six months of this year.

Omegna, a peaceful strip of land on lake Orta in Piedmont region, owes its niche in houseware to craftsmen who emigrated to Germany in the 18th century to work in pewter, then returned home to set up their own businesses.

The industry employs 1,130 people in a territory of 160,000, according to a July estimate by the chamber of commerce — 9 percent fewer than last year.

“In the boom years of the 60s there were about 40 houseware firms in Omegna,” recalled Alessi, whose creative drive helped transform his company into a top design brand.

That number has more than halved, although the resilience of the locals remains.

“This province is trying to overcome the current difficulties by focusing on those quality products that have made us famous,” said Roberta Costi at the chamber of commerce.

The combination of style and practicality that inspired Bialetti’s trademark “Moka express” and Lagostina’s first stainless steel saucepans — which are on display at the Museum of Modern Art of New York along with Alessi’s coffee machine “9090” — are key factors to counter the competition.

Sixteen houseware companies have teamed up with the chamber of commerce to explore new markets like Russia and develop innovations, for example by using nanotechnology, whose uses could include making stainless steel knives sharper.

Thirteen firms are due to showcase a new quality brand “Lago Maggiore Casalinghi” (“Lake Maggiore Houseware”) by the end of this year.

“Sales in the US and in Japan have suffered, while they have remained stable in Europe,” Alessi said in an interview at the firm’s offices in Crusinallo, near Omegna.

Exports account for 60 percent of Alessi’s annual revenues and the company employs around 200 international designers and 500 employees crafting 60 new projects a year.

“Even top companies like Lagostina are facing the consequences of outsourcing production,” said Costi at the chamber of commerce.

The stainless-steel cookware maker, founded by Carlo Lagostina and his son Emilio in 1901 and now owned by the French small appliances group SEB, is in talks with unions over possible redundancies among the 200 employees.

It has ruled out plant closures, saying “Made in Italy” branding retains strategic value: exports account for more than a third of its income.

“The group is firmly convinced about keeping R&D and high-end production in Omegna,” SEB said in a statement.

Coffee-machine maker Bialetti Industrie — founded in 1919 by Alberto Alessi’s grandfather, Alfonso Bialetti, and majority-owned by chairman and chief executive Francesco Ranzoni — reached an agreement in April with more than 90 percent of its creditors to keep credit lines open for another year.

Last June they approved a three-year business plan to boost revenues and reduce debts. The company’s stock, listed in Milan, trades at around 0.5100 euros, above a low of 0.164 euros reached in March. It launched in July 2007 at 2.50 euros.

People say it helps that family ties are so deep-rooted in this little industrial district, where 79 percent of the 5,000 craftsmanship firms are individually run.

When Alberto Alessi’s father Carlo died last August at 93, his wake was held at the factory. Only family members sit on the board. A reproduction of Carlo Alessi’s “Bombe” tea and coffee service — still the company’s most successful design after more than 50 years — stands outside the factory in Crusinallo.

“We are closely tied to this valley. Our family was born here,” Alessi said.

“If you ask me if our factory will still be in Omegna in 20 years, I can’t answer you,” he said. “But I can tell you that we need our skilled workforce to turn our ideas into reality.”

IN THE AIR: While most companies said they were committed to North American operations, some added that production and costs would depend on the outcome of a US trade probe Leading local contract electronics makers Wistron Corp (緯創), Quanta Computer Inc (廣達), Inventec Corp (英業達) and Compal Electronics Inc (仁寶) are to maintain their North American expansion plans, despite Washington’s 20 percent tariff on Taiwanese goods. Wistron said it has long maintained a presence in the US, while distributing production across Taiwan, North America, Southeast Asia and Europe. The company is in talks with customers to align capacity with their site preferences, a company official told the Taipei Times by telephone on Friday. The company is still in talks with clients over who would bear the tariff costs, with the outcome pending further

NEGOTIATIONS: Semiconductors play an outsized role in Taiwan’s industrial and economic development and are a major driver of the Taiwan-US trade imbalance With US President Donald Trump threatening to impose tariffs on semiconductors, Taiwan is expected to face a significant challenge, as information and communications technology (ICT) products account for more than 70 percent of its exports to the US, Chung-Hua Institution for Economic Research (CIER, 中華經濟研究院) president Lien Hsien-ming (連賢明) said on Friday. Compared with other countries, semiconductors play a disproportionately large role in Taiwan’s industrial and economic development, Lien said. As the sixth-largest contributor to the US trade deficit, Taiwan recorded a US$73.9 billion trade surplus with the US last year — up from US$47.8 billion in 2023 — driven by strong

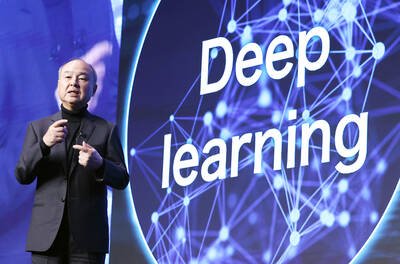

AI: Softbank’s stake increases in Nvidia and TSMC reflect Masayoshi Son’s effort to gain a foothold in key nodes of the AI value chain, from chip design to data infrastructure Softbank Group Corp is building up stakes in Nvidia Corp and Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the latest reflection of founder Masayoshi Son’s focus on the tools and hardware underpinning artificial intelligence (AI). The Japanese technology investor raised its stake in Nvidia to about US$3 billion by the end of March, up from US$1 billion in the prior quarter, regulatory filings showed. It bought about US$330 million worth of TSMC shares and US$170 million in Oracle Corp, they showed. Softbank’s signature Vision Fund has also monetized almost US$2 billion of public and private assets in the first half of this year,

POWELL SUCCESSOR: US Fed Governor Adriana Kugler’s resignation gives Donald Trump an opening on the board, potentially accelerating his decision on the next chair US President Donald Trump suddenly has a chance to fill an opening at the US Federal Reserve earlier than expected, after Fed Governor Adriana Kugler announced her resignation on Friday. It might also force him to pick the next Fed chair months sooner than he had anticipated. “The ball is now in Trump’s court,” LH Meyer/Monetary Policy Analytics Inc economist Derek Tang said. “Trump is the one who’s been putting pressure on the Fed to do this and that, and Trump says he wants to have his own people on. So now he has the opportunity.” Kugler’s exit unfolds amid unprecedented public pressure