Behind a giant solar factory, backhoes are digging away, preparing for a new wing that will quintuple production. Inside, an outspoken German executive named Boris Klebensberger is fretting about the color of the new carpet. Samples are perched on his window sill alongside floor plans.

Expanding a factory? Picking out carpeting?

Did anyone tell him there’s a recession?

PHOTO: NY TIMES NEWS SERVICE

Buoyed by the potential promise of a green economy, Klebensberger, who heads the US branch of SolarWorld AG, a company based in Bonn, Germany, is ramping up production of solar cells in a retrofitted factory that had its grand opening last October — in the teeth of the financial crisis.

“Was I worried about our position? No!” says Klebensberger, dismissing any hint that he was nervous at the opening.

And he remains just as bullish today. SolarWorld’s plant in Hillsboro, Oregon, which makes enough cells to fit 1,700 solar panels a day, is the biggest of its kind in the US.

For the residents of Hillsboro, and for the Oregon economy, SolarWorld’s presence is a welcome boon. Its employees enjoy being in start-up mode, while others like the cachet of working for a renewable-energy company.

“Green is the way to go,” says Michelle Zillig, who worked at Intel for 18 years before joining SolarWorld as a technician. “People can only have so many computers.”

At first glance, the timing of SolarWorld’s decision to invest US$500 million in the new site during a recession, in a state with an unemployment rate second only to Michigan’s, couldn’t have been worse. Prices for the company’s solar panels have slid about 15 percent since the factory opened, a result of growing competition and slowing demand, especially in Europe. Two manufacturers, GE Energy’s solar branch and BP Solar, have cut production in East Coast plants.

INCENTIVES

But new federal incentives to encourage renewable energy in the US will give the industry a boost, analysts say.

The recent stimulus package included grants for businesses and utilities that install solar energy systems, and the bank bailout package last year removed the dollar cap on a 30 percent tax credit for home installations. Makers of renewable energy equipment also received help in the stimulus package.

“I think the writing on the wall is the US is going to be the big market,” says Jesse Pichel, a solar analyst at Piper Jaffray.

The message for solar companies, Pichel says, is: “Get your butt over to the US if you want to participate and get some of that stimulus package money.”

The US lost its status as the world’s leading solar manufacturer in the 1990s as interest surged elsewhere. Now it makes little more than 5 percent of solar panels worldwide.

ROOM TO GROW

Even with federal support and positive buzz, only a fraction of 1 percent of the electricity in the US comes from solar panels, leaving ample room for the market to grow.

Germany, SolarWorld’s home, is at the same latitude as southern Alaska, often has cloudy skies and is a much smaller country than the US. Yet the number of installed solar panels in Germany is more than three times the amount in the US. Spain and Japan are also ahead.

“Germany is not a natural for solar, but they’ve had vision, and policy followed the vision, and industry growth followed the policy,” says Raju Yenamandra, the vice president for sales at SolarWorld in California.

For manufacturers, the low penetration rate of solar in the US spells opportunity. Companies lucky enough to still have financing are building or expanding operations in a range of states, including Oregon, Ohio and New Mexico.

As the German flag fluttering outside the SolarWorld factory in Oregon attests, foreign companies are largely driving the new US manufacturing push.

Klebensberger and his rivals are especially eager for solar to take off in the desert Southwest, where the sun beats down through often-cloudless skies. California has made a strong solar push, with the amount of solar power installed roughly doubling in 2008 from the previous year.

Recently, new installations of the type of rooftop-ready panels that SolarWorld makes have been growing strongly, with 70 percent more installed in the US last year than in 2007. In Europe, new installations roughly tripled last year, said Emerging Energy Research, an independent research firm. However, the European number is expected to fall sharply this year in the wake of a decision by the Spanish government to cut its solar subsidy.

For its part, SolarWorld made its bet on manufacturing in the US long before the stimulus package arrived. In 2006, it bought the solar division of the Shell Group, which operated factories in California and Washington. Klebensberger revamped the California factory, throttled back the existing facility in Washington and began scouting other sites in those states, as well as Alabama, Georgia and New Mexico.

“I don’t know how many brochures we got from states that offered us incentives and upfront money,” Klebensberger says.

The company ultimately settled on a semiconductor factory in Hillsboro that was built in the 1990s and swiftly abandoned after a downturn in the chip industry. Semiconductors are made from the same crystal material as solar panels, and having water and exhaust systems in place helped SolarWorld ramp up faster.

State incentives also helped: Oregon, which has been heavily recruiting wind and solar companies, provided SolarWorld with US$40 million in business tax credits.

POOL OF WORKERS

SolarWorld also gained access to a big pool of potential employees because it is situated in the heart of the Oregon “Silicon Forest,” surrounded by semiconductor plants and a short drive from a much larger Intel factory. SolarWorld’s team has swelled to more than 500, some of them temporary, which gets the company about halfway to its goal of 1,000 permanent workers by 2011. The company holds new-employee orientations each Monday.

Inside the plant, the factory floor combines the mild chaos and urgency of a start-up with the scale of a public company. In one room, orderly rows of cylindrical furnaces stand like so many trees and grow crystals weighing more than 100kg. The crystals are made from polysilicon, a derivative of sand, and form the core ingredient of the solar panels.

In other rooms, the cooked and cooled crystal ingots — looking like spent artillery shells — are sliced by machines into what are called wafers. Then they are made chemically suitable for generating electricity and are overlaid with electric wires, and a slim, dark cell emerges. (The cells, which resemble drink coasters, are sent to SolarWorld’s California plant to be strung together into the finished product that goes onto roofs.)

RAMPING UP

Many of the processes are still being automated, and the plant is also testing and expanding new systems in mid-production.

“I’ve got this radio here in case things go south,” says Willie Owens, an equipment engineer in goggles and jeans. He was testing new furnaces and water-cooling equipment.

If there were a big problem, he explains, he would have to hit a button within one minute to activate emergency systems.

The job, he says with relish, provides “an adrenaline rush sometimes.”

Like a number of other SolarWorld employees at all levels, Owens is a transplant from the semiconductor industry, whose big West Coast factories have suffered badly in the latest downturn. Hynix, for example, closed a plant in Eugene, Oregon, last year, resulting in the loss of about 1,100 jobs.

Even as SolarWorld charges ahead, adding new equipment and breaking ground for its factory expansion, there are daily reminders of the challenges ahead. The company’s share price has declined more than 30 percent in two years, to 21.05 euros (US$27.80), largely because of slowing demand and a growing number of manufacturers.

Asia has also become a manufacturing hub for solar power, and many panels from China have entered the market, although the recession has forced some companies to cut back. Suntech Power, a leading Chinese manufacturer, is now using just 55 percent of its factories’ capacity, though it, too, is looking for factory space in the US for the long term.

Like the rest of the industry, SolarWorld is also trying to adjust to the decline in panel prices, which are likely to keep falling into the summer, given the oversupply and the continuing credit crisis.

Klebensberger tries to put a positive spin on this, noting that the first quarter is always relatively weak because Europeans avoid installing panels during the winter.

For all of last year, the company’s sales grew at a heady 31 percent. But the pace of growth in the fourth quarter slowed considerably.

Industry-wide installations in the first quarter in California, the largest market in the US, remain robust. Installers there are wary, however. They say demand dried up in the last six months because companies lack financing and homeowners are more worried about their mortgages than sinking US$25,000 or more into making electricity on their roof.

Analysts say the first-quarter figures in California may have had a boost from projects that were already in the pipeline and that future numbers may be less robust. A year ago, installers say, they were calling manufacturers to ask for panels; now the situation is reversed, with manufacturers making sales calls.

COMPETITION

In the meantime, the competition among manufacturers is likely to intensify. Even as some of the weaker solar companies resort to layoffs, a number of big names including Schott, First Solar, SunPower and Sharp are building, expanding or looking to build manufacturing plants in the US. Sanyo, the Japanese electronics company, is building a solar wafer factory in Salem — Oregon’s capital — that is to begin production this fall.

Klebensberger relishes the competition and the boost it could give the US economy.

Solar energy can provide jobs and energy security, he says, “so it’s a way out of the crisis.”

NATIONAL SECURITY THREAT: An official said that Guan Guan’s comments had gone beyond the threshold of free speech, as she advocated for the destruction of the ROC China-born media influencer Guan Guan’s (關關) residency permit has been revoked for repeatedly posting pro-China content that threatens national security, the National Immigration Agency said yesterday. Guan Guan has said many controversial things in her videos posted to Douyin (抖音), including “the red flag will soon be painted all over Taiwan” and “Taiwan is an inseparable part of China,” while expressing hope for expedited “reunification.” The agency received multiple reports alleging that Guan Guan had advocated for armed reunification last year. After investigating, the agency last month issued a notice requiring her to appear and account for her actions. Guan Guan appeared as required,

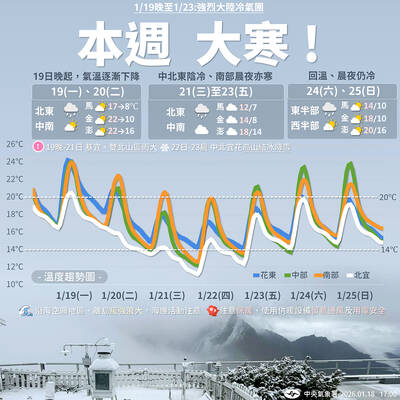

A strong cold air mass is expected to arrive tonight, bringing a change in weather and a drop in temperature, the Central Weather Administration (CWA) said. The coldest time would be early on Thursday morning, with temperatures in some areas dipping as low as 8°C, it said. Daytime highs yesterday were 22°C to 24°C in northern and eastern Taiwan, and about 25°C to 28°C in the central and southern regions, it said. However, nighttime lows would dip to about 15°C to 16°C in central and northern Taiwan as well as the northeast, and 17°C to 19°C elsewhere, it said. Tropical Storm Nokaen, currently

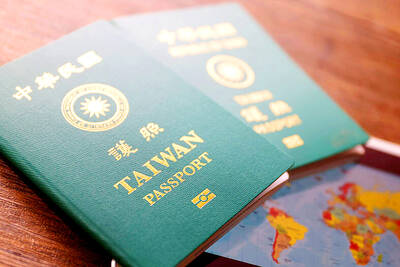

PAPERS, PLEASE: The gang exploited the high value of the passports, selling them at inflated prices to Chinese buyers, who would treat them as ‘invisibility cloaks’ The Yilan District Court has handed four members of a syndicate prison terms ranging from one year and two months to two years and two months for their involvement in a scheme to purchase Taiwanese passports and resell them abroad at a massive markup. A Chinese human smuggling syndicate purchased Taiwanese passports through local criminal networks, exploiting the passports’ visa-free travel privileges to turn a profit of more than 20 times the original price, the court said. Such criminal organizations enable people to impersonate Taiwanese when entering and exiting Taiwan and other countries, undermining social order and the credibility of the nation’s

‘SALAMI-SLICING’: Beijing’s ‘gray zone’ tactics around the Pratas Islands have been slowly intensifying, with the PLA testing Taiwan’s responses and limits, an expert said The Ministry of National Defense yesterday condemned an intrusion by a Chinese drone into the airspace of the Pratas Islands (Dongsha Islands, 東沙群島) as a serious disruption of regional peace. The ministry said it detected the Chinese surveillance and reconnaissance drone entering the southwestern parts of Taiwan’s air defense identification zone early yesterday, and it approached the Pratas Islands at 5:41am. The ministry said it immediately notified the garrison stationed in the area to enhance aerial surveillance and alert levels, and the drone was detected in the islands’ territorial airspace at 5:44am, maintaining an altitude outside the effective range of air-defense weaponry. Following