Shayne Myhand, the day-shift manager of Dell's flagship factory here, does a lot of chaperoning. As many as four or five times a day, he finds himself playing host to corporate chieftains and midlevel scouts who come to marvel at the dazzlingly efficient assembly plant that may be the best hope for keeping blue-collar jobs in the US rather than exporting them to the Far East.

A 31-year-old with a crisp, military-like bearing, Myhand begins each tour the same way, moving to a display case and grabbing an unimpressive wooden plaque commemorating Dell's production of 49,269 personal computers in the last three months of 1991.

PHOTO: THE NEW YORK TIMES

"On a good day, during peak demand, we'll exceed that number by lunchtime," he said, with a slight nod and a faint smile gracing his lips.

He told a visitor that even now, during the Christmas season rush, an order that hits the factory floor at 9am is typically stacked in the back of a truck motoring down an interstate highway by 1pm.

Inside Dell, the world's largest computer maker, executives study the assembly process with the intensity of Alfred Kinsey and his researchers. They wheel in video equipment to examine a work team's every movement, looking for any extraneous bends or wasted twists. Designers give one another high-fives for eliminating even a single screw from a product, because that represents a saving of roughly 4 seconds per machine built -- the time they've calculated it takes an employee, on average, to use the pneumatic screwdriver dangling above his or her head.

Computer software clocks the assembly-line performance of workers, whether they're putting together PCs or the servers and storage equipment that Dell sells to large companies. The most able are declared "master builders" and then videotaped so that others may watch and learn. The weak are told that it takes a special set of talents to cut it on the Dell factory floor -- and shown the door.

Steely-eyed cold, to be sure, but at a time when economists and politicians fret over the future of US manufacturing, Dell isn't just defying a global trend, it's helping to set the standard.

"When everybody is outsourcing -- when everybody is outsourcing -- Dell continues to manufacture in the United States because over two decades of fine-tuning, they've figured out how to do it cheaper and smarter," said Charles Wolf, an analyst at Needham & Co, who has been following Dell since 1991. He has also been reaping the financial rewards as a longtime Dell shareholder, seeing a 33-fold return on his investment.

"They're truly in the 21st century when it comes to manufacturing," Wolf said.

No other major computer maker produces computers in the US. Long ago, Dell's top rival, Hewlett-Packard, outsourced assembly of its PCs to third parties, primarily based in Asia, as did IBM, the world's third-largest PC maker. And IBM, which created the PC market in 1981, is leaving the business, announcing this month that it was selling its PC unit to Lenovo, the Chinese computer giant.

"It's been a long time since one of our competitors actually made a computer," said Michael Dell, the founder and chairman of the company that bears his name.

Dell, by contrast, operates three giant assembly plants in the US -- two in Austin and the third outside Nashville. Each is large enough to house six contiguous football fields. Last month, the company announced that it would build a fourth plant, twice as big as the others, near Winston-Salem, North Carolina. And, inside the company, executives talk about opening a fifth one, probably in Nevada, where it would build computers according to each customer's specifications. At a White House conference on the economy on Wednesday, Kevin Rollins, Dell's chief executive, said that the company makes all of its desktop computers right here in the US.

"None is outsourced; none is made in other countries and shipped in," he said.

Dell's decision to expand its US manufacturing presence, however, has nothing to do with patriotism. Executives here say their decisions are based on the bottom line as well as on geography; it is simply more efficient to stamp out computer equipment closer to the customer.

"The reason we continue to manufacture in the United States is that it's the optimal place to do so, and we can do it most cost effectively," said John Hamlin, who oversees Dell's entire consumer line.

Few rivals know that better than Lenovo itself. The questions that many analysts have been asking in the wake of the IBM deal is how well Lenovo, based in Beijing, can compete with Dell outside of China, given how cheaply Dell can make its machines.

Dell has run a factory in Xiamen, China, since 1998 -- but that's to produce computer equipment that the company sells to its Asian customers. Similarly, Dell's factory in Limerick, Ireland, makes machines for Europe. This month, Dell announced that his company would probably build a second European plant sometime soon.

Dell is also bucking global trends on another front. In an era when a call center is more likely to be in India than Indiana, the company has announced that it is building a new customer assistance facility in Oklahoma City. Earlier this year, it opened a call center in Edmonton, Alberta. And while Dell's laptops are produced in Malaysia, they are built by Dell employees working inside a Dell-owned factory.

"I tell employees all the time that we're in a race on costs," said Dick Hunter, who, as the Dell executive who oversees manufacturing in the US, is Myhand's boss.

"When we lose the race on costs to Asia or wherever, that puts our own security in jeopardy," Hunter said.

Ever since 1984, when Michael Dell began selling personal computers from his University of Texas dorm room, his company has been able to sell cheaper PCs by cutting out the middleman, selling directly via the phone or, nowadays, the Internet. But the reason Dell continues to dominate as a low-cost leader -- whether selling a PC, a server or, more recently, plasma televisions and portable music players -- is its fanatical determination to save every penny it can. Dell may not quite be the Henry Ford of our time, but his company is certainly the Wal-Mart of the high-technology industry, for better or worse.

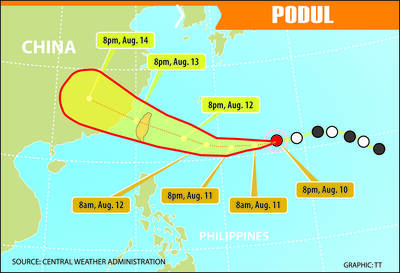

GET TO SAFETY: Authorities were scrambling to evacuate nearly 700 people in Hualien County to prepare for overflow from a natural dam formed by a previous typhoon Typhoon Podul yesterday intensified and accelerated as it neared Taiwan, with the impact expected to be felt overnight, the Central Weather Administration (CWA) said, while the Directorate-General of Personnel Administration announced that schools and government offices in most areas of southern and eastern Taiwan would be closed today. The affected regions are Tainan, Kaohsiung and Chiayi City, and Yunlin, Chiayi, Pingtung, Hualien and Taitung counties, as well as the outlying Penghu County. As of 10pm last night, the storm was about 370km east-southeast of Taitung County, moving west-northwest at 27kph, CWA data showed. With a radius of 120km, Podul is carrying maximum sustained

Tropical Storm Podul strengthened into a typhoon at 8pm yesterday, the Central Weather Administration (CWA) said, with a sea warning to be issued late last night or early this morning. As of 8pm, the typhoon was 1,020km east of Oluanpi (鵝鑾鼻), Taiwan’s southernmost tip, moving west at 23kph. The storm carried maximum sustained winds of 119kph and gusts reaching 155kph, the CWA said. Based on the tropical storm’s trajectory, a land warning could be issued any time from midday today, it added. CWA forecaster Chang Chun-yao (張竣堯) said Podul is a fast-moving storm that is forecast to bring its heaviest rainfall and strongest

TRAJECTORY: The severe tropical storm is predicted to be closest to Taiwan on Wednesday and Thursday, and would influence the nation to varying degrees, a forecaster said The Central Weather Administration (CWA) yesterday said it would likely issue a sea warning for Tropical Storm Podul tomorrow morning and a land warning that evening at the earliest. CWA forecaster Lin Ting-yi (林定宜) said the severe tropical storm is predicted to be closest to Taiwan on Wednesday and Thursday. As of 2pm yesterday, the storm was moving west at 21kph and packing sustained winds of 108kph and gusts of up to 136.8kph, the CWA said. Lin said that the tropical storm was about 1,710km east of Oluanpi (鵝鑾鼻), Taiwan’s southernmost tip, with two possible trajectories over the next one

TALKS CONTINUE: Although an agreement has not been reached with Washington, lowering the tariff from 32 percent to 20 percent is still progress, the vice premier said Taiwan would strive for a better US tariff rate in negotiations, with the goal being not just lowering the current 20-percent tariff rate, but also securing an exemption from tariff stacking, Vice Premier Cheng Li-chiun (鄭麗君) said yesterday. Cheng made the remarks at a news conference at the Executive Yuan explaining the new US tariffs and the government’s plans for supporting affected industries. US President Donald Trump on July 31 announced a new tariff rate of 20 percent on Taiwan’s exports to the US starting on Thursday last week, and the Office of Trade Negotiations on Friday confirmed that it