The production value in Taiwan’s semiconductor industry this year is expected to soar 31.8 percent from last year to NT$3.6 trillion (US$129 billion), outpacing 10.1 percent growth in the global semiconductor industry, market researcher the Market Intelligence and Consulting Institute (產業情報研究所) said yesterday.

The Taipei-based researcher attributed the strong outlook for the local semiconductor industry to demand for chips used in notebook computers amid a COVID-19 pandemic-induced stay-at-home economy, as well as emerging applications from 5G and artificial intelligence to automotive electronics.

Production in the foundry segment, a pillar of Taiwan’s semiconductor industry, is to expand 20 percent annually to NT$1.9 trillion, driven by higher chip prices as demand continues to outstrip supply, the institute said.

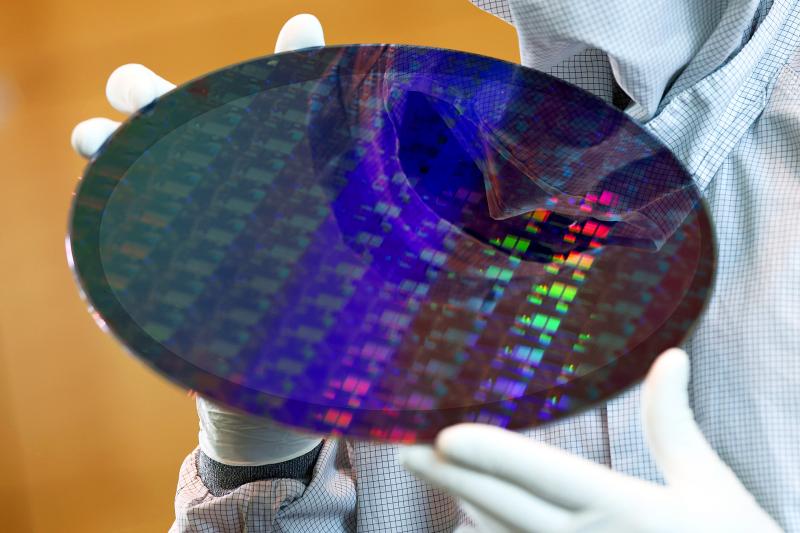

Photo: Bloomberg

Chipmakers would increase prices, passing on increases in manufacturing costs, it said.

“Semiconductor shortages have become a new global norm,” said Cheng Kai-an (鄭凱安), a senior industry analyst at the institute.

“It has become a new business model for foundry companies to ink long-term supply agreements and collect prepayments,” Cheng said in a statement. “Foundry companies are raising prices to reflect higher costs and to boost gross margin. Hiking chip prices will also help avert overbooking, which could lead to supply-demand imbalance.”

For suppliers of DRAM and flash memory chips, prices are to peak in the second half of this year, leaving little room for further upticks, he said.

Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s biggest foundry service provider, said that it expects its revenue to expand more than 20 percent this year from last year.

TSMC has reportedly raised prices by 10 to 20 percent for new orders.

Local chip testing and packaging service providers are to increase product value by 25 percent this year from last year, benefiting from strong demand, price increases and supply constraints, the institute said.

On top of that, some local companies are to receive orders transferred from peers, as some plants were forced to halt production due to COVID-19 restrictions in Malaysia, the market researcher said.

Chip designers, led by MediaTek Inc (聯發科), are expected to report growth of 33 percent year-on-year this year to cross the NT$1 trillion mark for the first time, to NT$1.1 trillion, it said.

Demand is rising for a wide range of chips, helping to propel revenue growth, Cheng said.

However, supply of microcontroller units, power management ICs and radio frequency ICs might remain tight due to a capacity squeeze at foundries, he said.

The institute said that it expects a global chip crunch to continue next year and in 2023, as it takes time for chipmakers to ramp up new production and for governments to build local supply chains.

Over the next three years, the compound annual growth rate of production value in Taiwan’s foundry sector is expected to be 10.5 percent, it said.

Chip designers and memorychip makers are expected to grow 7.9 percent and 7.5 percent respectively, while chip testers and packagers would expand 7.2 percent, it said.

Stephen Garrett, a 27-year-old graduate student, always thought he would study in China, but first the country’s restrictive COVID-19 policies made it nearly impossible and now he has other concerns. The cost is one deterrent, but Garrett is more worried about restrictions on academic freedom and the personal risk of being stranded in China. He is not alone. Only about 700 American students are studying at Chinese universities, down from a peak of nearly 25,000 a decade ago, while there are nearly 300,000 Chinese students at US schools. Some young Americans are discouraged from investing their time in China by what they see

Taiwan Transport and Storage Corp (TTS, 台灣通運倉儲) yesterday unveiled its first electric tractor unit — manufactured by Volvo Trucks — in a ceremony in Taipei, and said the unit would soon be used to transport cement produced by Taiwan Cement Corp (TCC, 台灣水泥). Both TTS and TCC belong to TCC International Holdings Ltd (台泥國際集團). With the electric tractor unit, the Taipei-based cement firm would become the first in Taiwan to use electric vehicles to transport construction materials. TTS chairman Koo Kung-yi (辜公怡), Volvo Trucks vice president of sales and marketing Johan Selven, TCC president Roman Cheng (程耀輝) and Taikoo Motors Group

MAJOR DROP: CEO Tim Cook, who is visiting Hanoi, pledged the firm was committed to Vietnam after its smartphone shipments declined 9.6% annually in the first quarter Apple Inc yesterday said it would increase spending on suppliers in Vietnam, a key production hub, as CEO Tim Cook arrived in the country for a two-day visit. The iPhone maker announced the news in a statement on its Web site, but gave no details of how much it would spend or where the money would go. Cook is expected to meet programmers, content creators and students during his visit, online newspaper VnExpress reported. The visit comes as US President Joe Biden’s administration seeks to ramp up Vietnam’s role in the global tech supply chain to reduce the US’ dependence on China. Images on

New apartments in Taiwan’s major cities are getting smaller, while old apartments are increasingly occupied by older people, many of whom live alone, government data showed. The phenomenon has to do with sharpening unaffordable property prices and an aging population, property brokers said. Apartments with one bedroom that are two years old or older have gained a noticeable presence in the nation’s six special municipalities as well as Hsinchu county and city in the past five years, Evertrust Rehouse Co (永慶房產集團) found, citing data from the government’s real-price transaction platform. In Taipei, apartments with one bedroom accounted for 19 percent of deals last