A group representing Germany’s machinery industry yesterday said that it expects production to drop 17 percent this year as the sector struggles with the fallout from the COVID-19 pandemic and international trade tensions.

Orders for machinery, a major German export, were down 16 percent in the first seven months of the year compared with a year earlier, while production declined 14 percent, the Mechanical Engineering Industry Association said.

The association cited the effects of the pandemic, protectionism in international trade and change affecting the auto industry — a key customer.

Official data released yesterday showed that Germany’s overall exports were up 4.7 percent in July compared with the previous month.

That was the third consecutive month-on-month gain following huge declines at the height of Europe’s COVID-19 lockdowns — but a much smaller increase than the 14.9 percent seen in June. In year-on-year terms, exports fell 11 percent.

That is in line with recent data showing that increases in German factory orders and industrial production also slowed in July.

The government last week said that the economy was performing better than expected following the easing of Germany’s lockdown restrictions, which were less drastic than in some other European countries.

It is now predicting that the economy would contract 5.8 percent this year, a somewhat more optimistic outlook than the 6.3 percent it forecast in late April.

AUTO INDUSTRY

Germany’s struggling auto industry needs more government aid, including a purchasing bonus for less-polluting combustion-engine vehicles, to help weather the pandemic, German Minister for Transport, Building and Urban Development Andreas Scheuer said.

The number of electric vehicles available is limited and there are combustion-engine models on the market that are relatively clean in terms of air pollution, Scheuer said in an interview with DLF radio yesterday.

“We are talking about a key German technology and many, many jobs and families depend on it,” Scheuer said, ahead of talks later yesterday chaired by German Chancellor Angela Merkel between government officials, regional leaders and auto executives on the future of the industry.

Merkel’s ruling coalition is divided over the need for a purchasing incentive for combustion vehicles, with Scheuer’s party — the Bavaria-based Christian Social Union — arguing in favor and others insisting that the focus should be on promoting electric vehicles.

Merkel last week said that she was aware of the CSU’s position, but saw no need to expand the government’s stimulus package for the time being.

Germany has already sought to lift auto sales by introducing purchasing subsidies of as much as 9,000 euros (US$10,632) per electric vehicle.

Scheuer, who was to attend yesterday’s “car summit,” said that more government support was needed to help automakers and parts suppliers cope with the fallout from the pandemic.

Additional reporting by Bloomberg

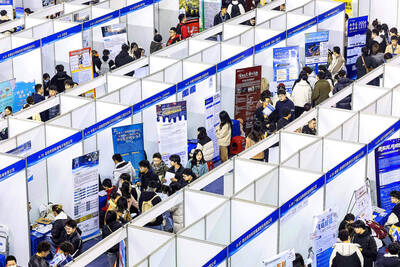

Stephen Garrett, a 27-year-old graduate student, always thought he would study in China, but first the country’s restrictive COVID-19 policies made it nearly impossible and now he has other concerns. The cost is one deterrent, but Garrett is more worried about restrictions on academic freedom and the personal risk of being stranded in China. He is not alone. Only about 700 American students are studying at Chinese universities, down from a peak of nearly 25,000 a decade ago, while there are nearly 300,000 Chinese students at US schools. Some young Americans are discouraged from investing their time in China by what they see

Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday reported record sales for the first quarter, which analysts attributed to solid demand for emerging technologies. Consolidated revenue totaled NT$592.64 billion (US$18.51 billion) in the January-to-March period, up 16.5 percent from a year earlier, but down 5.26 percent from the previous quarter, TSMC said in a statement. The first-quarter revenue beat analysts’ average projection of NT$579.5 billion, Bloomberg News reported. That performance lends weight to expectations that the world’s most valuable chipmaker would return to solid growth this year after weathering a post-COVID-19-pandemic cratering of smartphone and computer sales. TSMC is budgeting

HUALIEN BRANCH: The company had been planning to rebuild the hotel before it was damaged in the quake and vowed to give affected employees the option to transfer The owner of Chateau de Chine Hualien (花蓮翰品酒店) is planning to lay off 86 workers after shutting down the hotel due to damage it sustained in a powerful earthquake on Wednesday last week, the Ministry of Labor said yesterday. The hotel has submitted a layoff report to the Hualien County Government and expects to let 69 workers go this month and 17 next month, the ministry said. LDC Hotels & Resorts Group (雲朗觀光集團), the owner of Chateau de Chine Hualien, confirmed the layoff plan in a statement yesterday. LDC said the hotel has been closed since Wednesday last week when the temblor occurred

US CONSCULTANT: The US Department of Commerce’s Ursula Burns is a rarely seen US government consultant to be put forward to sit on the board, nominated as an independent director Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday nominated 10 candidates for its new board of directors, including Ursula Burns from the US Department of Commerce. It is rare that TSMC has nominated a US government consultant to sit on its board. Burns was nominated as one of seven independent directors. She is vice chair of the department’s Advisory Council on Supply Chain Competitiveness. Burns is to stand for election at TSMC’s annual shareholders’ meeting on June 4 along with the rest of the candidates. TSMC chairman Mark Liu (劉德音) was not on the list after in December last