Almost 15 years ago, Richard Livengood, a researcher for Intel, used an exotic machine known as a focused ion beam to painstakingly deposit a missing wire on the surface of a 486-microprocessor chip.

The chip was then placed into a personal computer, which, to the astonishment of Livengood and a small group of Intel engineers, booted Microsoft's Windows operating system without a hitch.

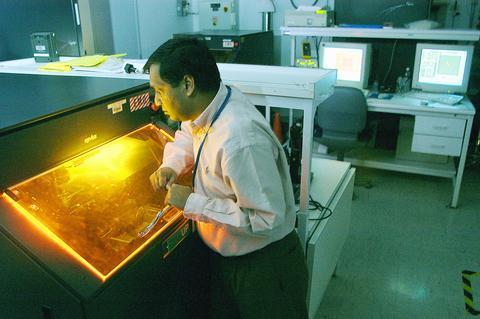

PHOTO: NY TIMES

The technique, now referred to as silicon nanosurgery and routinely used at nine Intel chip factories around the world, has completely transformed the way modern computer chips are developed.

Around the Clock

In a building next to Intel's corporate headquarters here, the focused ion beam technology is now employed -- often around the clock -- as part of an arsenal of microimaging and "surgical" tools used to locate design flaws and performance bottlenecks and make changes in circuit wires that are frequently no more than several hundred atoms in width.

In a cluster of windowless rooms known as the debug lab, the company also uses lasers and photo detectors, often aimed at single transistors.

One of the newest machines, using what is called laser-assisted device alteration, makes it possible to change the speed of the tiny switches that make up a silicon chip. This allows Intel chip designers to quickly fine-tune circuits to generate more speed from their microprocessors.

Similar systems are widely used throughout the semiconductor industry today to accelerate the time it takes to go from prototype chips to manufacturing.

Rather than keeping the technologies it pioneers proprietary, Intel often licenses them to semiconductor equipment makers in an effort to keep the industry advancing uniformly as well as to ensure a less-expensive supply of the multimillion-dollar machines.

At the same time, Intel tries to keep some technologies in reserve to maintain a lead in an industry in which a technology generation lasts about two years.

Molecular-Scale

The company's silicon surgeons are proof that chip makers are now within a decade of creating electronic devices made from molecular-scale components.

"We've moved well into the nano world," said Livengood, who has worked at Intel for 17 years.

Techniques for peering into semiconductor chips date to the early 1980s, when Intel scientists pioneered an approach known as voltage contrast technology.

Timing Problems

By scanning an electron beam across the top of a running computer chip, they were able to watch each transistor and wire in the chip switch on and off. It made it possible to look for hard-to-diagnose timing problems, like a transistor that was turning on and off too slowly.

During that decade, however, the industry was forced to find new techniques when it developed sophisticated methods for packaging chips, known as "flip chip" modules. This advance made it possible to attach many more wires to each chip to move data in and out more quickly.

The task of looking inside working chips that had been turned upside down and sealed shut was much more complicated. To gain access to the transistors again, Livengood's researchers developed an approach based on etching away most of the back of the chip until only an ultrathin sheet of silicon was left. It acted as a window, making it possible to use ion beams and lasers to see the transistors as they turned on and off.

The researchers were then able to devise ways to use the ion beams to cut holes less than a micron in diameter through the back of the chip. The holes make it possible to both cut metal wires and add new ones inside the chip.

On some occasions, Intel technicians even fashion ultrasmall capacitors or change the width and thickness of the metal lines to speed up or slow down the switching speed of transistors.

Tweaking

The tools are used routinely now as part of the process of tuning new chips as they are readied for manufacturing. Livengood estimated that it was possible to increase speeds as much as 20 percent by tweaking individual transistors in a process similar to that of a piano tuner adjusting different wires on a piano.

Recently, Intel's president, Paul S. Otellini, said the company was changing its strategy to focus less on pure chip speed and more on adding features to its future microprocessors.

That will not give Livengood's design team any chance to relax, however.

"Moore's Law hasn't changed," he said, referring to the industry's track record of constantly shrinking the size of transistors.

ROLLER-COASTER RIDE: More than five earthquakes ranging from magnitude 4.4 to 5.5 on the Richter scale shook eastern Taiwan in rapid succession yesterday afternoon Back-to-back weather fronts are forecast to hit Taiwan this week, resulting in rain across the nation in the coming days, the Central Weather Administration said yesterday, as it also warned residents in mountainous regions to be wary of landslides and rockfalls. As the first front approached, sporadic rainfall began in central and northern parts of Taiwan yesterday, the agency said, adding that rain is forecast to intensify in those regions today, while brief showers would also affect other parts of the nation. A second weather system is forecast to arrive on Thursday, bringing additional rain to the whole nation until Sunday, it

CONDITIONAL: The PRC imposes secret requirements that the funding it provides cannot be spent in states with diplomatic relations with Taiwan, Emma Reilly said China has been bribing UN officials to obtain “special benefits” and to block funding from countries that have diplomatic ties with Taiwan, a former UN employee told the British House of Commons on Tuesday. At a House of Commons Foreign Affairs Committee hearing into “international relations within the multilateral system,” former Office of the UN High Commissioner for Human Rights (OHCHR) employee Emma Reilly said in a written statement that “Beijing paid bribes to the two successive Presidents of the [UN] General Assembly” during the two-year negotiation of the Sustainable Development Goals. Another way China exercises influence within the UN Secretariat is

CHINA REACTS: The patrol and reconnaissance plane ‘transited the Taiwan Strait in international airspace,’ the 7th Fleet said, while Taipei said it saw nothing unusual The US 7th Fleet yesterday said that a US Navy P-8A Poseidon flew through the Taiwan Strait, a day after US and Chinese defense heads held their first talks since November 2022 in an effort to reduce regional tensions. The patrol and reconnaissance plane “transited the Taiwan Strait in international airspace,” the 7th Fleet said in a news release. “By operating within the Taiwan Strait in accordance with international law, the United States upholds the navigational rights and freedoms of all nations.” In a separate statement, the Ministry of National Defense said that it monitored nearby waters and airspace as the aircraft

Taiwan’s first drag queen to compete on the internationally acclaimed RuPaul’s Drag Race, Nymphia Wind (妮妃雅), was on Friday crowned the “Next Drag Superstar.” Dressed in a sparkling banana dress, Nymphia Wind swept onto the stage for the final, and stole the show. “Taiwan this is for you,” she said right after show host RuPaul announced her as the winner. “To those who feel like they don’t belong, just remember to live fearlessly and to live their truth,” she said on stage. One of the frontrunners for the past 15 episodes, the 28-year-old breezed through to the final after weeks of showcasing her unique