Taiwan High Speed Rail Corp (THSRC) yesterday said it aims to raise the percentage of its high-speed rail system that is maintained or built by local service providers and manufacturers from 15 percent to 30 percent by 2022.

The high-speed rail operator signed a contract with China Steel Corp yesterday morning, authorizing the state-run steel firm to build 12 multifunctional electric wire maintenance vehicles in the next 66 months.

About 60 percent of the technology and parts that are to be used to build the vehicles would be produced in Taiwan, THSRC said.

Photo: Cheng Wei-chi, Taipei Times

The contract is an important milestone because it signifies a step further toward the localization of the nation’s railway industry, THSRC chairman Chiang Yao-chung (江耀宗) said.

“We have accumulated 11 years of experience in maintaining the high-speed rail system, which helps, as we are designing new maintenance vehicles that we will use in the near future,” he said. “We hope that the step we take today will take the railway toward building an indigenous train system.”

The company has 27 electric wire maintenance vehicles, which are manufactured in Japan or Germany, Chiang said, adding that they have been in use for 40 to 50 years and have different functions.

“From our experience in maintaining the high-speed rail system, we believe that the electric wire maintenance vehicles provide a safe platform for workers that allows them to work more efficiently. Therefore, we are working with China Steel to design a maintenance vehicle that has a bigger work platform and can turn in different directions,” he said.

In addition to having more domestically produced maintenance vehicles, the company would establish key performance indicators to ensure that the percentage of the high-speed rail system that is maintained or produced by domestic service providers or manufacturers is doubled in five years, he said.

THSRC’s contract with China Steel is estimated to cost NT$123.2 million (US$4 million), the company said, adding that some of it would be used to repair and maintain electric wires in 2021.

The high-speed rail system has revolutionized Taiwan since it was launched in 2007, Minister of Transportation and Communications Wu Hong-mo (吳宏謀) said, adding that he hopes that the THSRC-China Steel partnership will motivate others to follow suit.

The railway industry presents many business opportunities, from the high-speed rail system, the Taiwan Railways Administration system and the mass rapid transit systems to light rail systems, Wu said, dismissing allegations that the construction of railway systems would become a financial burden on local governments.

“International tourists like to travel in Taipei, New Taipei City and Keelung because it is convenient for them to transfer between railway systems,” he said. “This is a chicken-and-egg question, and nobody knows what the future may hold.”

“We think that railway transportation is the way to help form metropolitan areas in northern, central and southern Taiwan,” Wu said.

Minister of Economic Affairs Sheng Jong-chin (沈榮津) said that THSRC would soon make public a list of items to be used for railway maintenance, as well as their quantities and specifications, for domestic companies interested in producing them.

Former president Ma Ying-jeou’s (馬英九) mention of Taiwan’s official name during a meeting with Chinese President Xi Jinping (習近平) on Wednesday was likely a deliberate political play, academics said. “As I see it, it was intentional,” National Chengchi University Graduate Institute of East Asian Studies professor Wang Hsin-hsien (王信賢) said of Ma’s initial use of the “Republic of China” (ROC) to refer to the wider concept of “the Chinese nation.” Ma quickly corrected himself, and his office later described his use of the two similar-sounding yet politically distinct terms as “purely a gaffe.” Given Ma was reading from a script, the supposed slipup

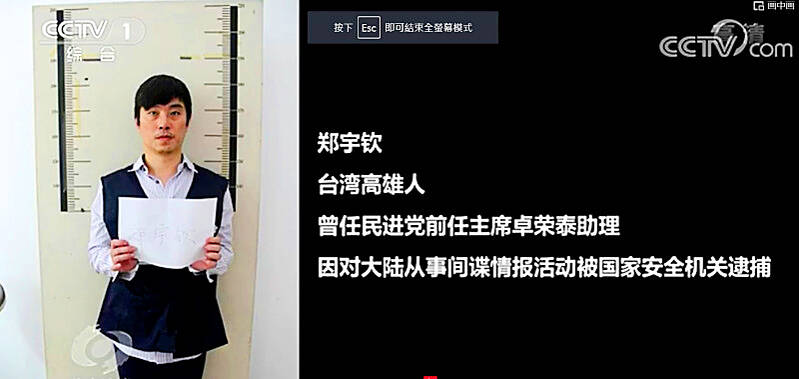

Former Czech Republic-based Taiwanese researcher Cheng Yu-chin (鄭宇欽) has been sentenced to seven years in prison on espionage-related charges, China’s Ministry of State Security announced yesterday. China said Cheng was a spy for Taiwan who “masqueraded as a professor” and that he was previously an assistant to former Cabinet secretary-general Cho Jung-tai (卓榮泰). President-elect William Lai (賴清德) on Wednesday last week announced Cho would be his premier when Lai is inaugurated next month. Today is China’s “National Security Education Day.” The Chinese ministry yesterday released a video online showing arrests over the past 10 years of people alleged to be

THE HAWAII FACTOR: While a 1965 opinion said an attack on Hawaii would not trigger Article 5, the text of the treaty suggests the state is covered, the report says NATO could be drawn into a conflict in the Taiwan Strait if Chinese forces attacked the US mainland or Hawaii, a NATO Defense College report published on Monday says. The report, written by James Lee, an assistant research fellow at Academia Sinica’s Institute of European and American Studies, states that under certain conditions a Taiwan contingency could trigger Article 5 of NATO, under which an attack against any member of the alliance is considered an attack against all members, necessitating a response. Article 6 of the North Atlantic Treaty specifies that an armed attack in the territory of any member in Europe,

The bodies of two individuals were recovered and three additional bodies were discovered on the Shakadang Trail (砂卡礑) in Taroko National Park, eight days after the devastating earthquake in Hualien County, search-and-rescue personnel said. The rescuers reported that they retrieved the bodies of a man and a girl, suspected to be the father and daughter from the Yu (游) family, 500m from the entrance of the trail on Wednesday. The rescue team added that despite the discovery of the two bodies on Friday last week, they had been unable to retrieve them until Wednesday due to the heavy equipment needed to lift