A team of researchers from National Tsing Hua University might take battery research to a new level, according to a scientific article.

The article published in the international peer-reviewed journal Nano Letters suggested refining red phosphorus to make anodes for batteries due to the material’s “abundance and a high theoretical [energy] capacity.”

The article said that while red phosphorus is already used in lithium-ion batteries, it is mainly in the form of carbon-phosphorus composites to improve “phosphorus’ extremely low conductivity and large volume change during the cycling process.”

Photo courtesy of National Tsing Hua University

The team conducted experiments on red phosphorus by large-scale synthesis of red phosphorus nanoparticles (RPNPs) with ethylene glycol in the presence of cetyltrimethylammonium bromide in ambient environment.

According to Tuan Hsing-yu (段興宇), one of the authors of the article, red phosphorus theoretically has more than seven times the electrical capacity of graphite, but due to its extremely low conductivity, it cannot be recharged.

Common methods involved heating up the red phosphorus to improve conductivity, which brought up the question of depleting the material, Tuan said.

Tuan said he wanted to break with tradition and after many years of analyzing data, he found phosphorus triiodide, which was used for the solution synthesis of iodine-doped RPNPs.

Iodine-doping was speculated to be the key to significantly improving the conductivity of RPNPs, the article said.

RPNP was proven in tests to have a high specific capacity, a long cycling life, and an outstanding rate capability, Tuan said.

Giving the batteries of Apple smartphones as an example, Tuan said batteries that need 6g of graphite could be made with only 1g of RPNP, which would enable the production of lighter, smaller batteries with longer lives.

Tuan said the team is applying for patents in numerous nations for the new method.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater

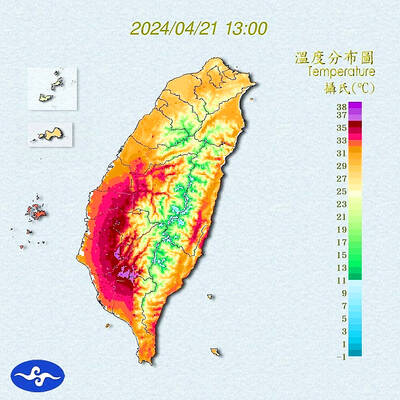

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching