National Taipei University of Technology researchers have developed a new fabric-coating technique to produce quick-drying cloth, which they said could help the textile industry carve a niche in the global market even in the face of China’s “red supply chain.”

University professor Rwei Syang-peng (芮祥鵬) yesterday said that his team took two years to develop an incomplete surface-coating technique for unidirectional moisture transport and sweat diffusion, which could drain sweat swiftly and achieve a better cooling effect than Gore-Tex fabrics, a waterproof and breathable material.

Water-repellent fabrics are created using what is called the lotus effect, Rwei said. Microscopic structures on the leaves of the lotus plant prevent water droplets from attaching to the leaves, so water sits on papillae on the leaf’s surface without soaking in.

Water-repellent fabrics have a nanoscopic hairy structure on their surface that mimics the papillae on lotus leaves to keep out liquids, Rwei added.

The team’s incomplete coating technique leaves parts of the fabric “naked” — not covered by the water-repelling, hairy structures — so moisture can be swiftly drained through uncoated areas, Rwei said, adding that the incomplete coating could dissipate moisture three times faster than conventional gauze materials.

Gore-Tex fabrics are generally made into jackets or overcoats because they are too rough to be worn in contact with the skin, but the team’s technique can be used to make fabric with a gentle texture that could be made into lingerie and sportswear, he said, adding that they have been approached by international clothing companies.

The incomplete coating technique can be used on many fabrics, including cotton, nylon and polyester, he said.

“Our technique could give Taiwanese businesses an edge over Chinese competitors and help the textile industry carve a niche in the global market of functional fabrics, which has an annual value of US$70 billion to US$80 billion,” he said.

The team also developed a new technique to coat Teflon on kitchenware or high-temperature conveyor belts in food factories.

The team uses specially designed slot die to inject Teflon solution onto glass fiber, which is heated to 320oC to firmly attach the solution, Rwei said. The technique could the amount of Teflon solution used by 60 percent compared with the traditional dipping method, while no toxic residue would be left on the finished surface.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

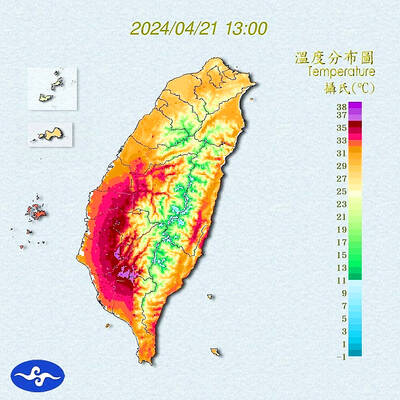

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater