The nation’s brick-making industry has long been in decline, but the last brickworks in Hualien County is seeking to survive by turning itself into a tourist attraction and a museum for students to experience brick-making for themselves.

Jifeng Brickworks was founded in 1968 as a joint venture between former Hualien County commissioner Huang Fu-shou (黃福壽) and former Hualien County Council speaker Lee Chuan-fang (李傳芳).

Originally using only a traditional circular kiln, the company began with a capacity to produce 200,000 bricks a month. In 1995, capacity was raised to 3 million bricks a month after an automated production line with a tunnel kiln was built.

Photo: Hua Meng-ching, Taipei Times

However, as bricks are no longer the main building materials, Jifeng is now the only brick factory in the county that is still in operation today.

After his father, the late chairman of the company, Hsieh Te-an (謝得安), died in August, Hsieh Chien-hui (謝建輝) took over as chief executive officer.

He said that due to the low demand for bricks in Hualien and Taitung counties, western Taiwan has become the major market for his factory, but the firm’s prices are not very competitive because of the high cost of freight. These days, the factory operates only six months of the year.

Thinking that it was a waste to keep the factory running for only half the year, Hishe Chien-hui decided to turn the brickworks into a tourist attraction and a museum for elementary and junior-high school students — and other visitors — to experience do-it-yourself brick-making sessions, and to take a walk in the tunnel kiln.

Visitors may draw whatever they like on bricks before the bricks are fired to dry in the kiln.

Chang Lien-fu (張連富), an employee who has worked for more than a decade in the brickworks, said that in the final phase of brick-making, workers place unfinished bricks onto carts and push the cars through the tunnel-like 140m-long drying kiln.

Chang said that each cart can carry up to 5,100 bricks at a time, and the kiln can take up to 20 carts at a time. The bricks are fired at temperatures of between 850oC and 900oC for six hours.

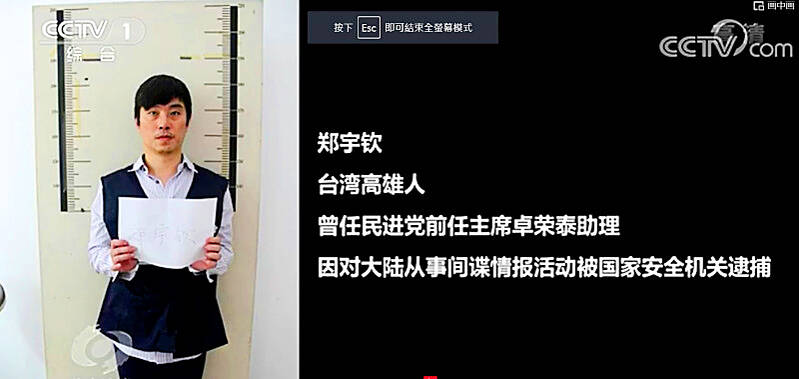

Former Czech Republic-based Taiwanese researcher Cheng Yu-chin (鄭宇欽) has been sentenced to seven years in prison on espionage-related charges, China’s Ministry of State Security announced yesterday. China said Cheng was a spy for Taiwan who “masqueraded as a professor” and that he was previously an assistant to former Cabinet secretary-general Cho Jung-tai (卓榮泰). President-elect William Lai (賴清德) on Wednesday last week announced Cho would be his premier when Lai is inaugurated next month. Today is China’s “National Security Education Day.” The Chinese ministry yesterday released a video online showing arrests over the past 10 years of people alleged to be

THE HAWAII FACTOR: While a 1965 opinion said an attack on Hawaii would not trigger Article 5, the text of the treaty suggests the state is covered, the report says NATO could be drawn into a conflict in the Taiwan Strait if Chinese forces attacked the US mainland or Hawaii, a NATO Defense College report published on Monday says. The report, written by James Lee, an assistant research fellow at Academia Sinica’s Institute of European and American Studies, states that under certain conditions a Taiwan contingency could trigger Article 5 of NATO, under which an attack against any member of the alliance is considered an attack against all members, necessitating a response. Article 6 of the North Atlantic Treaty specifies that an armed attack in the territory of any member in Europe,

LIKE FAMILY: People now treat dogs and cats as family members. They receive the same medical treatments and tests as humans do, a veterinary association official said The number of pet dogs and cats in Taiwan has officially outnumbered the number of human newborns last year, data from the Ministry of Agriculture’s pet registration information system showed. As of last year, Taiwan had 94,544 registered pet dogs and 137,652 pet cats, the data showed. By contrast, 135,571 babies were born last year. Demand for medical care for pet animals has also risen. As of Feb. 29, there were 5,773 veterinarians in Taiwan, 3,993 of whom were for pet animals, statistics from the Animal and Plant Health Inspection Agency showed. In 2022, the nation had 3,077 pediatricians. As of last

XINJIANG: Officials are conducting a report into amending an existing law or to enact a special law to prohibit goods using forced labor Taiwan is mulling an amendment prohibiting the importation of goods using forced labor, similar to the Uyghur Forced Labor Prevention Act (UFLPA) passed by the US Congress in 2021 that imposed limits on goods produced using forced labor in China’s Xinjiang region. A government official who wished to remain anonymous said yesterday that as the US customs law explicitly prohibits the importation of goods made using forced labor, in 2021 it passed the specialized UFLPA to limit the importation of cotton and other goods from China’s Xinjiang Uyghur region. Taiwan does not have the legal basis to prohibit the importation of goods