Tsai Fu-liang (蔡福良) and his wife, Chang Yu-hsuan (張毓萱), had never envisaged themselves starting a vinegar-making business, but life saw things otherwise.

According to Tsai, everything started when he was sent to China to manage a company factory in 2010.

Not two months after arriving in China, Tsai learned that his son had come down with Kawasaki syndrome, and he began to contemplate leaving his job to stay with his wife, who he had met while he was studying at National Pingtung University of Science and Technology’s Department of Food Science after serving his mandatory military service, and son.

Photo: CNA

Kawasaki syndrome is an autoimmune disease mostly seen in children under five years of age, in which the body’s medium-sized blood vessels become inflamed.

Though the syndrome was treated, Tsai said doctors cautioned that they would have to monitor his son’s health until he hit puberty, causing the couple to become more concerned with matters of health in general. At that point, Tsai had even vowed that he would become a vegetarian for life.

“I had been thinking all that year what I would do when I returned to Taiwan,” Tsai said, adding that he had at first considered going into the alcohol-making business, but opted against it due to the potential effects of alcohol on the human body.

However, it occurred to Tsai that he could perhaps aim for something similar, as vinegar is produced by fermenting alcohol.

It is a healthier product than alcohol, Tsai said, adding that from his observations in China — where he noticed many people taking a cup of vinegar after dinner to aid in digestion — there was evidently a demand for the product.

Tsai began collecting a variety of information on vinegar production while he was still in China and began researching production processes almost immediately upon his return to Taiwan.

Tsai said he started trial production almost at the same time as the research, and if he had any questions, he asked a former colleague from university, Hsu Che-jung (許哲榕), who had written his thesis on vinegar made from the flowers of the roselle plant.

He also struck up a chance conversation with a farmer in Pingtung County’s Gaoshu Township (高樹) and learned that farmers were suffering from over- production of jujube in the region, he said.

“It gave me the idea to use jujube as the primary ingredient,” Tsai said, adding that over the years he has branched off into using other materials. However, he insists on using only agricultural products produced in Taiwan.

“I spent the first two years dumping a lot of failed types of vinegar,” Tsai said, adding that the process was extremely time-sensitive and one moment of fermenting too long would spell the failure of an entire pot.

Tsai also said that he would purchase any bottle of vinegar on the market that was labeled “naturally made,” but found the majority of claims to be untrue, adding that most vinegar brands seen on the market were either acetic acid mixed with sugar or other fruit juices, or they were made using a different method.

Tsai that wanted to make a brand of vinegar that would be healthy not only for his family, but also his future customers, adding that he adhered to the old way of making vinegar, coupled with a membrane filtration technique he had learned at school.

Wishing to garner feedback for his product, Tsai brought his vinegar to traditional markets and sold it from his stand for two months. He also invited people to participate in online questionnaires.

Tsai’s product has since received awards from Germany’s Red Dot Design Award — a prestigious prize that was first awarded in 1955 — last year, as well as a bronze medal in the Pentaward Concept Award — a worldwide competition exclusively devoted to packaging design and open to anyone.

The winners receive bronze, silver, gold, platinum or diamond awards depending on the creative quality of their work.

Tsai and Chang’s business finally took off last year following receipt of the awards, which enabled the couple to label the product as a “boutique” item and open outlets in department stores.

After some persuasion by the couple, Hsu had also joined the business and the three are planning on expanding the business.

They hoped to make a mark on the vinegar industry in Taiwan, they said.

Looking back on the venture, Chang professed that she had her doubts whether it was worth it to start such a business, but her doubts vanished when Tsai told her: “This is not a career, it’s a calling and it is the right path.”

“I was behind him 100 percent after that,” Chang said, adding that Hsu was also happy to join the team, as he was now doing something that he really wanted to be doing.

Pointing to their insistence on using agricultural products from Taiwan for ingredients, the couple also said that they hoped their efforts would help agriculture in Taiwan take off again.

A group of Taiwanese-American and Tibetan-American students at Harvard University on Saturday disrupted Chinese Ambassador to the US Xie Feng’s (謝鋒) speech at the school, accusing him of being responsible for numerous human rights violations. Four students — two Taiwanese Americans and two from Tibet — held up banners inside a conference hall where Xie was delivering a speech at the opening ceremony of the Harvard Kennedy School China Conference 2024. In a video clip provided by the Coalition of Students Resisting the CCP (Chinese Communist Party), Taiwanese-American Cosette Wu (吳亭樺) and Tibetan-American Tsering Yangchen are seen holding banners that together read:

UNAWARE: Many people sit for long hours every day and eat unhealthy foods, putting them at greater risk of developing one of the ‘three highs,’ an expert said More than 30 percent of adults aged 40 or older who underwent a government-funded health exam were unaware they had at least one of the “three highs” — high blood pressure, high blood lipids or high blood sugar, the Health Promotion Administration (HPA) said yesterday. Among adults aged 40 or older who said they did not have any of the “three highs” before taking the health exam, more than 30 percent were found to have at least one of them, Adult Preventive Health Examination Service data from 2022 showed. People with long-term medical conditions such as hypertension or diabetes usually do not

POLICE INVESTIGATING: A man said he quit his job as a nurse at Taipei Tzu Chi Hospital as he had been ‘disgusted’ by the behavior of his colleagues A man yesterday morning wrote online that he had witnessed nurses taking photographs and touching anesthetized patients inappropriately in Taipei Tzu Chi Hospital’s operating theaters. The man surnamed Huang (黃) wrote on the Professional Technology Temple bulletin board that during his six-month stint as a nurse at the hospital, he had seen nurses taking pictures of patients, including of their private parts, after they were anesthetized. Some nurses had also touched patients inappropriately and children were among those photographed, he said. Huang said this “disgusted” him “so much” that “he felt the need to reveal these unethical acts in the operating theater

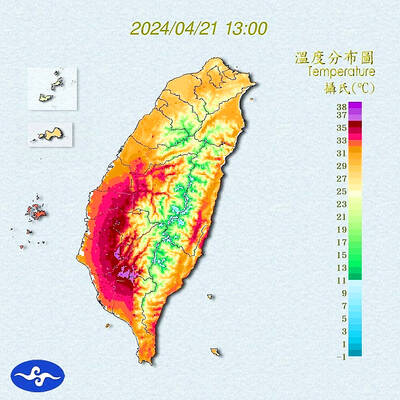

Heat advisories were in effect for nine administrative regions yesterday afternoon as warm southwesterly winds pushed temperatures above 38°C in parts of southern Taiwan, the Central Weather Administration (CWA) said. As of 3:30pm yesterday, Tainan’s Yujing District (玉井) had recorded the day’s highest temperature of 39.7°C, though the measurement will not be included in Taiwan’s official heat records since Yujing is an automatic rather than manually operated weather station, the CWA said. Highs recorded in other areas were 38.7°C in Kaohsiung’s Neimen District (內門), 38.2°C in Chiayi City and 38.1°C in Pingtung’s Sandimen Township (三地門), CWA data showed. The spell of scorching