The Council of Agriculture said on Wednesday that it is implementing a Certified Agricultural Standards (CAS) logo for down jackets and other types of down garments starting next year so that consumers can better discern genuine products from apparel made of other materials.

Taiwan is the world’s third-largest exporter of processed down products, the council said, adding that the nation’s exports of processed down products each year is equivalent to three times the weight of the Tokyo Tower.

Down, an excellent thermal insulator and padding material, is the layer of fluffy feathers found underneath the outer feathers of ducks, geese and other species of bird.

Photo: Chung Li-hua, Taipei Times

As there are no current standardization regulations, the council is to institute a CAS logo for domestic production of down garments. The CAS logo represents government certification of premium agricultural produce and related products.

Under the program, down content has to be at least 70 percent for the product to receive a CAS logo, so consumers are able to tell which garments are genuine “down.”

Chiang Wen-chuan (江文全), a section chief at the council’s Department of Animal Industry, said that under current certification, garments containing between 20 percent and 90 percent down can be labeled “down products.”

However, most producers agree that only garments with more than 70 percent down should be labeled “down products.”

Chiang said CAS certification would stipulate down content between 70 percent and 95 percent. Therefore consumers will be able to rely on the CAS logo to avoid buying fake down products.

Council data showed that Taiwanese down processing companies import raw down from foreign sources. The down is then sorted, rinsed and dried, before being sorted by weight and shape, and being exported as high-grade down.

Council statistics show that the nation imported 20,000 tonnes of down and other feathered material last year and exported 1.2 tonnes. The import value of down and other feathered material last year was NT$4.38 billion (US$150 million) and exports totaled NT$6.84 billion.

Domestic production of down is at about 2,300 tonnes a year, about 20 percent of processed down used in the nation.

Council officials said domestic down producers have an advantage as down can be transported to factories within a “golden window” of 24 hours, for the initial washing and rising process. Down processed within the window maintains its freshness, preventing the onset of mold growth. It therefore produces a better insulator which has a longer storage period.

Many of the down jackets and beddings on the market are a mix of down and “plumage,” Chiang said.

Plumage is the fine silky material made from the remains of feathers after the shaft has been removed and the rest crushed.

There is a big difference between the insulating properties of down and plumage. The price of raw down is between NT$2,000 and NT$3,500 per kilogram, so for a down jacket, the down content would cost at least NT$2,000.

If the jacket is too cheap to be true, for example less than NT$1,000, consumers should question whether it is a genuine down product, he said.

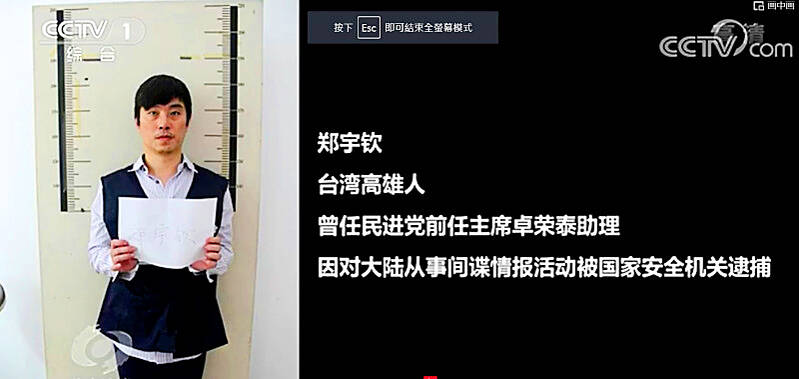

Former Czech Republic-based Taiwanese researcher Cheng Yu-chin (鄭宇欽) has been sentenced to seven years in prison on espionage-related charges, China’s Ministry of State Security announced yesterday. China said Cheng was a spy for Taiwan who “masqueraded as a professor” and that he was previously an assistant to former Cabinet secretary-general Cho Jung-tai (卓榮泰). President-elect William Lai (賴清德) on Wednesday last week announced Cho would be his premier when Lai is inaugurated next month. Today is China’s “National Security Education Day.” The Chinese ministry yesterday released a video online showing arrests over the past 10 years of people alleged to be

THE HAWAII FACTOR: While a 1965 opinion said an attack on Hawaii would not trigger Article 5, the text of the treaty suggests the state is covered, the report says NATO could be drawn into a conflict in the Taiwan Strait if Chinese forces attacked the US mainland or Hawaii, a NATO Defense College report published on Monday says. The report, written by James Lee, an assistant research fellow at Academia Sinica’s Institute of European and American Studies, states that under certain conditions a Taiwan contingency could trigger Article 5 of NATO, under which an attack against any member of the alliance is considered an attack against all members, necessitating a response. Article 6 of the North Atlantic Treaty specifies that an armed attack in the territory of any member in Europe,

LIKE FAMILY: People now treat dogs and cats as family members. They receive the same medical treatments and tests as humans do, a veterinary association official said The number of pet dogs and cats in Taiwan has officially outnumbered the number of human newborns last year, data from the Ministry of Agriculture’s pet registration information system showed. As of last year, Taiwan had 94,544 registered pet dogs and 137,652 pet cats, the data showed. By contrast, 135,571 babies were born last year. Demand for medical care for pet animals has also risen. As of Feb. 29, there were 5,773 veterinarians in Taiwan, 3,993 of whom were for pet animals, statistics from the Animal and Plant Health Inspection Agency showed. In 2022, the nation had 3,077 pediatricians. As of last

XINJIANG: Officials are conducting a report into amending an existing law or to enact a special law to prohibit goods using forced labor Taiwan is mulling an amendment prohibiting the importation of goods using forced labor, similar to the Uyghur Forced Labor Prevention Act (UFLPA) passed by the US Congress in 2021 that imposed limits on goods produced using forced labor in China’s Xinjiang region. A government official who wished to remain anonymous said yesterday that as the US customs law explicitly prohibits the importation of goods made using forced labor, in 2021 it passed the specialized UFLPA to limit the importation of cotton and other goods from China’s Xinjiang Uyghur region. Taiwan does not have the legal basis to prohibit the importation of goods