A stalwart of the persimmon processing industry for more than three decades, 55-year-old Liu Li-chien (劉理鑑) from Hsinchu County has brought new life to a traditional industry that has been battered by low-priced products smuggled in from China.

When the industry was still in its heyday, dried persimmons could fetch between NT$150 and NT$220 per catty (0.6kg), with the highest price of NT$350 a catty recorded at a night market in Greater Kaohsiung.

However, things took a turn for the worse about 28 years ago, when the Taiwanese persimmon sector was crippled by an incursion of smuggled persimmons from China, which brought down the price of locally grown persimmons to a record low of NT$100 per catty.

Photo: Huang Mei-chu, Taipei Times

Before Chinese smuggling became rampant, a middleman had offered to provide Liu with low-cost Chinese persimmons for NT$23 a catty, an opportunity that seemed too good to turn down.

Despite the temptation, Liu, proprietor of Hsinchu-based Wei Wei Jia Tourist Orchard, flatly rejected the offer out of conscience and an insistence on quality.

“Only one out of four Chinese persimmons do not taste astringent. As my mother always said, one should only make honest money,” Liu said. “Besides, peddling Chinese persimmons would help only my own business. What should Taiwanese persimmon farmers do then?”

The manufacture of dried persimmons is contingent on “the mercy of the weather,” he said.

In the best-case scenario, the northerly wind blowing from September to December would be strong and dry enough — acting as a “natural drying machine” — to accelerate the drying process of the golden fruits.

However, in most cases, manufacturers have to brave freezing temperatures to undertake a series of drying steps in an effort to prevent batches of laboriously harvested persimmons from perishing.

Born into a persimmon farming family, Liu started helping out with the family business at the age of five. In 1980, he and his father invented a drying machine to mimic the strong autumn wind.

Their brainchild, which could dry persimmons into a beautiful golden-yellow color, was soon copied by other orchard owners. The prevalence of the machine not only made the production of persimmon cakes far more time-efficient, but also launched an “industrial revolution” in the industry.

However, as Liu’s persimmon cakes have to be first dried, then roasted during a rainy day — a time-consuming processing method that gives the fruits a chewy taste, but also a less appealing appearance — his orchard started losing ground to other competitors that only used the drying machine.

Between 1987 and 1993, Liu’s business went from bad to worse in the face of fierce competition from both Taiwanese and Chinese persimmons.

At his worst, Liu earned less than NT$2,000 in retail revenue for an entire season, compared with the average quarterly profit of more than NT$1 million earned by other dried persimmon producers.

If not for the loyal support of a handful of wholesalers, including Chen Lien-tsai (陳連財) and Chan Yi-kuo (詹益國), who have been placing stable orders for Liu’s persimmon products for a long time, he might have given up.

Liu saw a silver lining when photography instructor Wu Ying-feng (吳應鳳), who was captivated by Wei Wei Jia’s traditional processing factory, started leading students to photograph the farm and factory each year.

Through the Internet, a group of women clad in headscarfs printed with Hakka traditional floral patterns, holding bamboo sieves filled with semi-dried persimmons while turning them, became the iconic image of Liu’s orchard, earning them the name “persimmon cake grandmas” (柿餅婆婆).

Another opportunity for Liu emerged nine years ago when an outsourcing contractor hired by the Ministry of Economic Affairs visited the orchard.

The delegation was surprised to discover a wooden beam that had been dyed brown by the persimmon juice left on the hands of Liu’s mother — a finding that blazed the trail for the development of persimmon dye in Taiwan and led to the establishment of the Hsinchu County Persimmon Dye Cultural Association.

Long regarded as a waste product, persimmons’ reddish-orange skin is rich in natural tannic acid and collagen, and dye extracted from it has good color fastness and can create a leather-like quality.

The beam was named the “Memorial Column of Parents” (懷親柱) and is now on display at Liu’s tourist orchard.

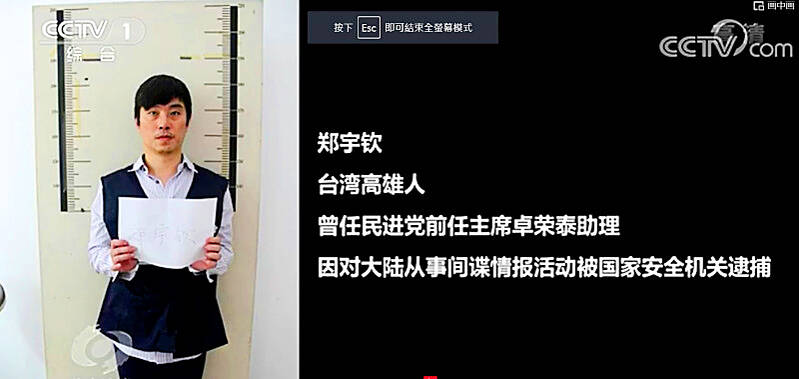

Former Czech Republic-based Taiwanese researcher Cheng Yu-chin (鄭宇欽) has been sentenced to seven years in prison on espionage-related charges, China’s Ministry of State Security announced yesterday. China said Cheng was a spy for Taiwan who “masqueraded as a professor” and that he was previously an assistant to former Cabinet secretary-general Cho Jung-tai (卓榮泰). President-elect William Lai (賴清德) on Wednesday last week announced Cho would be his premier when Lai is inaugurated next month. Today is China’s “National Security Education Day.” The Chinese ministry yesterday released a video online showing arrests over the past 10 years of people alleged to be

THE HAWAII FACTOR: While a 1965 opinion said an attack on Hawaii would not trigger Article 5, the text of the treaty suggests the state is covered, the report says NATO could be drawn into a conflict in the Taiwan Strait if Chinese forces attacked the US mainland or Hawaii, a NATO Defense College report published on Monday says. The report, written by James Lee, an assistant research fellow at Academia Sinica’s Institute of European and American Studies, states that under certain conditions a Taiwan contingency could trigger Article 5 of NATO, under which an attack against any member of the alliance is considered an attack against all members, necessitating a response. Article 6 of the North Atlantic Treaty specifies that an armed attack in the territory of any member in Europe,

LIKE FAMILY: People now treat dogs and cats as family members. They receive the same medical treatments and tests as humans do, a veterinary association official said The number of pet dogs and cats in Taiwan has officially outnumbered the number of human newborns last year, data from the Ministry of Agriculture’s pet registration information system showed. As of last year, Taiwan had 94,544 registered pet dogs and 137,652 pet cats, the data showed. By contrast, 135,571 babies were born last year. Demand for medical care for pet animals has also risen. As of Feb. 29, there were 5,773 veterinarians in Taiwan, 3,993 of whom were for pet animals, statistics from the Animal and Plant Health Inspection Agency showed. In 2022, the nation had 3,077 pediatricians. As of last

XINJIANG: Officials are conducting a report into amending an existing law or to enact a special law to prohibit goods using forced labor Taiwan is mulling an amendment prohibiting the importation of goods using forced labor, similar to the Uyghur Forced Labor Prevention Act (UFLPA) passed by the US Congress in 2021 that imposed limits on goods produced using forced labor in China’s Xinjiang region. A government official who wished to remain anonymous said yesterday that as the US customs law explicitly prohibits the importation of goods made using forced labor, in 2021 it passed the specialized UFLPA to limit the importation of cotton and other goods from China’s Xinjiang Uyghur region. Taiwan does not have the legal basis to prohibit the importation of goods