The Samsung brand is best known for its smartphones and wide-screen TVs. Yet behind the scenes, the conglomerate is also making a name as a contract manufacturer of complex medicines to treat diseases such as cancer.

On a piece of reclaimed land along South Korea’s western coast, Samsung BioLogics Co is building a US$740 million factory that is to give it the capacity to become the No. 1 producer by volume of a class of drugs called biologics, many of which are derived from mammal cells.

The Samsung group diversified into the pharmaceutical sector in 2011. Now, it is mobilizing its expertise in semiconductor making and engineering to make the way biologics are produced more efficient.

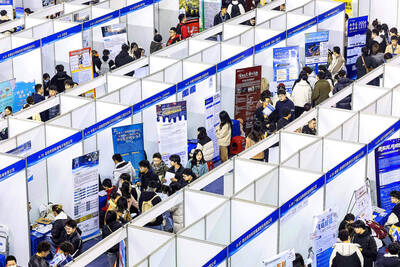

Photo: Bloomberg

The market for biologic medicines, which are used for everything from cancer to arthritis, is projected to exceed US$223.7 billion by 2021, according to a Bloomberg Intelligence analysis.

Being a force in biologics is crucial to Samsung — and South Korea. Galaxy smartphones and other consumer electronics face intense competition from Apple Inc and Chinese brands such as Huawei Technologies Co (華為), and Samsung is grappling with the arrest of de facto leader Jay Y. Lee in a scandal that brought down former South Korean president Park Geun-hye. Meanwhile, the broader economy needs new industries as shipbuilding and heavy manufacturing slow.

If the past 40 years of global economic growth were fueled by technology, the next are to be fueled by where that converges with healthcare, Samsung BioLogics chief executive officer Kim Tae-han said.

In an interview at company headquarters in Incheon, Kim said he is preparing to ramp up production and is in negotiations for more than 15 new contracts.

The Samsung board gave him the green light and US$2 billion to start the business about six years ago, he said.

However, on the strength of demand and business performance, “I’ve already spent US$3 billion,’’ he said.

Sales totaled 107.6 billion won (US$96.36 million) in the first quarter, a 2.1 percent year-on-year increase, although the unit still posted a net loss.

More than 2,000 construction workers — most with experience building semiconductor facilities — are buzzing around the factory site about an hour’s drive from Seoul. It is called Edison and is the company’s third drug facility. Its five floors encompass 34m, making way for custom-made vats that are so big some shoot through several floors.

Biologic drugs are grown from cells. That necessitates a more complex manufacturing process than typical pills — a mixture of chemicals — but makes biologics more effective and capable of being targeted toward certain diseases.

Building a biologic plant is similar to building one for semiconductors. There are clean rooms that cannot tolerate dust or other contamination, so Edison is being built without nuts or bolts to prevent any drilling. Everything is welded and tilted to fit together.

One day, “contract manufacturing” could extend to helping clients build the factories, Kim said.

Stephen Garrett, a 27-year-old graduate student, always thought he would study in China, but first the country’s restrictive COVID-19 policies made it nearly impossible and now he has other concerns. The cost is one deterrent, but Garrett is more worried about restrictions on academic freedom and the personal risk of being stranded in China. He is not alone. Only about 700 American students are studying at Chinese universities, down from a peak of nearly 25,000 a decade ago, while there are nearly 300,000 Chinese students at US schools. Some young Americans are discouraged from investing their time in China by what they see

Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday reported record sales for the first quarter, which analysts attributed to solid demand for emerging technologies. Consolidated revenue totaled NT$592.64 billion (US$18.51 billion) in the January-to-March period, up 16.5 percent from a year earlier, but down 5.26 percent from the previous quarter, TSMC said in a statement. The first-quarter revenue beat analysts’ average projection of NT$579.5 billion, Bloomberg News reported. That performance lends weight to expectations that the world’s most valuable chipmaker would return to solid growth this year after weathering a post-COVID-19-pandemic cratering of smartphone and computer sales. TSMC is budgeting

MAJOR DROP: CEO Tim Cook, who is visiting Hanoi, pledged the firm was committed to Vietnam after its smartphone shipments declined 9.6% annually in the first quarter Apple Inc yesterday said it would increase spending on suppliers in Vietnam, a key production hub, as CEO Tim Cook arrived in the country for a two-day visit. The iPhone maker announced the news in a statement on its Web site, but gave no details of how much it would spend or where the money would go. Cook is expected to meet programmers, content creators and students during his visit, online newspaper VnExpress reported. The visit comes as US President Joe Biden’s administration seeks to ramp up Vietnam’s role in the global tech supply chain to reduce the US’ dependence on China. Images on

US CONSCULTANT: The US Department of Commerce’s Ursula Burns is a rarely seen US government consultant to be put forward to sit on the board, nominated as an independent director Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday nominated 10 candidates for its new board of directors, including Ursula Burns from the US Department of Commerce. It is rare that TSMC has nominated a US government consultant to sit on its board. Burns was nominated as one of seven independent directors. She is vice chair of the department’s Advisory Council on Supply Chain Competitiveness. Burns is to stand for election at TSMC’s annual shareholders’ meeting on June 4 along with the rest of the candidates. TSMC chairman Mark Liu (劉德音) was not on the list after in December last